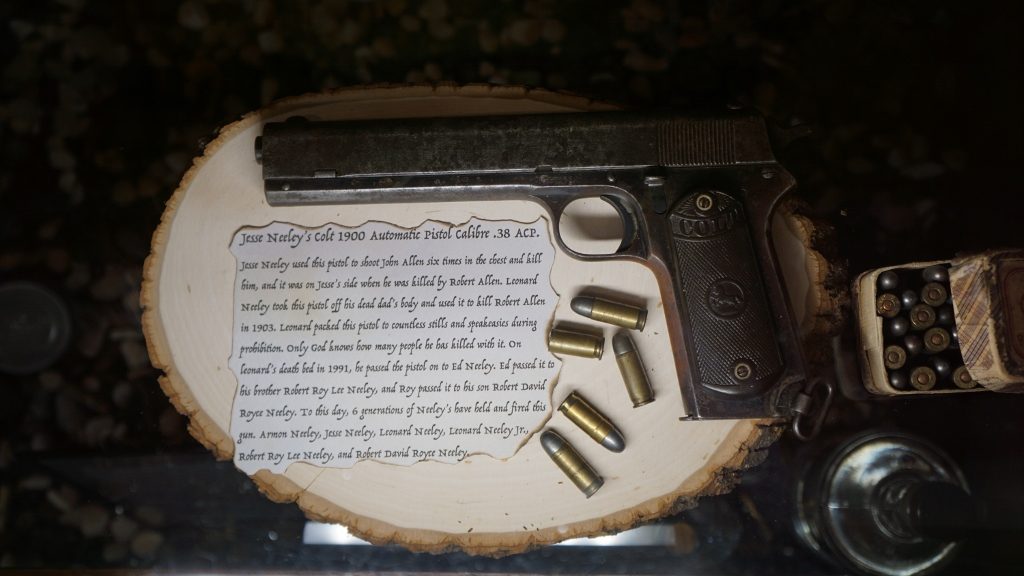

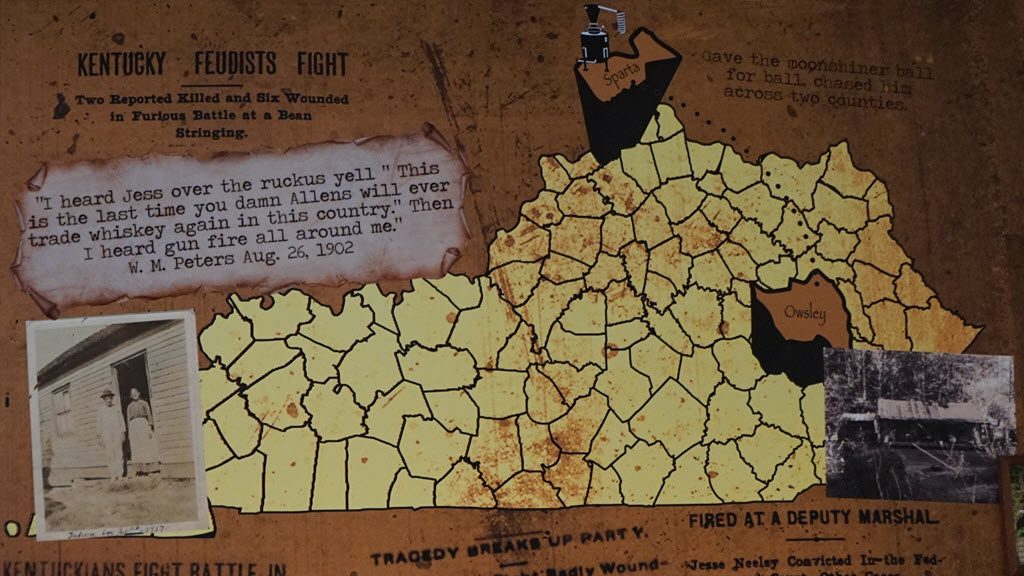

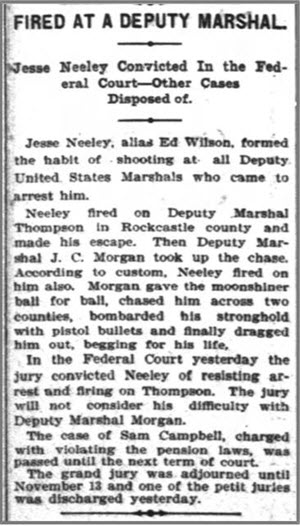

Startup craft spirits distilleries are often small family run operations. In the case of Neeley Family Distillery it’s all of those things – a startup, family owned and a maker of small batch craft spirits. Throw in a 100 plus years of family history of moonshining, gun fights and time in the pen and you’ve just met the Neeley family.

Investment Decision – Go Big or Go Small?

When Royce first started his business plan for the distillery he went big. The initial plan called for building a $5 to $10 million distillery operation. He later decided he didn’t want to take on all that debt and to stay small to get started. He looked at lots of different options on what would make his craft spirits distillery successful. He knew he needed great product but figured he had that with some old family recipes. One of the things that was key to him was investing in a great location that would one day make for a great stop on the Kentucky Bourbon Trail and he found one.

Location, Location, Location

Sparta is home to The Kentucky Speedway a 1.5 mile racetrack that sits on 1,000 acres. The track offers 125 private RV sites, 650 infield RV sites, 3,000 reserved campsites, 30,000 free parking spaces and has seating for 87,000 NASCAR fans. The distillery sits at the entrance to one of two main gates. On the first race day since opening in July, the distillery had over 3,500 visitors in one weekend. They are also on the way to Belterra Casino Resort & Spa, a southern Indiana riverboat casino with nearly 1,300 gaming devices, 45 table games and nine poker tables and nearly a million visitors a year. And, as if that wasn’t enough, they sit within an hour of Boone County Distilling, New Riff Distilling, Second Sight Spirits, Six Mile Creek Distillery (now under construction) and Buffalo Trace Distillery. I do believe you can put a big check mark next to the location requirement.

The rustic hand hewn looking building that houses the distillery was also a family affair. Royce’s dad is the owner of a construction company. He built the entire distillery building and barrel warehouse. Make a note of the pond you see in the picture here. It’s not just for looks but we’ll tell you about that in a minute.

Looking back at the decision to go small Royce said, “It doesn’t take a lot for us (to be successful) because our overhead is so low. It’s me, Mom and Dad that run it and my girlfriend Lindsay. (Her full-time job is being a nurse.) I’m the lead distiller, I handle everything on that side of things. When I need help I call a couple of family members and they’ll come down and help me for the day. My overhead is very low. That was my business plan.”

A Behind the Scenes Distillery Tour

The distillery itself is a true craft spirits distillery with lots of standard equipment, some pieces that do double duty and other pieces that were hand crafted or repurposed for a second life in the distillery.

Most of their grains are produced locally with the exception of the malted barley that comes from BSG Distilling in easy to handle 50 lb bags. The grains get heated and cooked in one of the three pot stills from Affordable Distillery Equipment. They have two 200 gallon hybrid pot stills and one 100 gallon pot still for a total of 500 gallons. All three are electric oil immersion stills. He generally uses the smaller still as a double thumper still. Royce has compared his utility bills to some other craft distillers of similar sizes that operate gas fired stills. He says that his electric utility bills to run the stills are comparable to others running gas. The design of these stills allows them to be converted to natural gas if he were to choose to do so in the future.

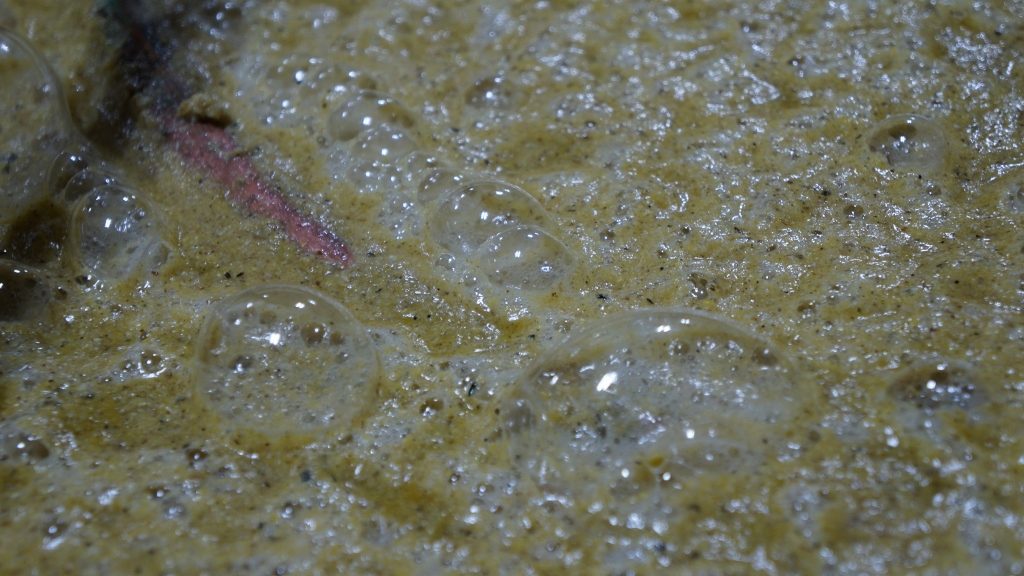

Once cooked, the mash is pumped to 300 gallon plastic fermentation totes. If you take a close look at the totes you’ll see that these are re-purposed food grade tanks. Royce says he likes these tanks right now because they are lightweight and easy to move around the distillery as needed. The day we were there he was running a wheated bourbon with mashbill of 80% corn, 15% wheat and 5% malted barley.

To help drop the mash temperature in the fermentation tanks he uses a homemade copper coil that’s running water from the pond on the side yard. Royce explained, “That’s pond water running through those coils. It runs hot, everything runs hot back out onto the roof, it hits the downspout and shoots back into the pond. So, I use the pond water to cool everything. That’s probably the best ROI that you see here is that pond. Every month I get a $35 water bill which is great!” It’s a pretty clever way to recycle water.

After four to five days of fermentation, the mash is sent back to the pot stills for distillation. Though the stills have room for plates, he says he doesn’t use them now. He said, “Through experience and trying stuff out, there is nothing like something that’s double pot distilled. A full stripping run and then a finish in a pot.”

Once he extracts the hearts of the run his spirits are dumped into American Oak barrels. For now, he’s using a variety of 10, 15, 30 and 53 gallon barrels all with a #3 char. He said, “We are doing a little bit of all of them until we get passed the two year mark and then we’ll do all 53s after that.”

In a small craft distillery, the owner has to be a jack of all trades. The day we were there he had to take a break to jump on the Bobcat to unload some 10 and 15 gallon barrels that had just arrived from The Barrel Mill.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Though his bourbon isn’t old enough to dump yet, he does have a dumping station that he’s already using. He does some contract distilling and bottling for David James Whiskey. The contract work helps to pay the bills while his bourbon ages.

Future Member of the Kentucky Bourbon Trail Craft Tour

The Neeley Family Distillery recently joined the Kentucky Distillers’ Association as the 35th member of the association. They joined as the 25th craft member, making less than 1,000 barrels per year. They expect to join the Kentucky Bourbon Trail Craft Tour in about a year.

“Kentucky’s signature Bourbon and distilled spirits industry has been built on the innovation and perseverance of young entrepreneurs,” Kentucky Distillers’ Association President Eric Gregory said. “We’re excited to see Royce keeping up that tradition and proudly welcome the Neeley Family Distillery to the KDA.”

Neeley Family Distillery products are available in the retail shop at the distillery and are distributed by Kentucky Eagle.

A Photo Tour of the Neeley Family Distillery

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Twitter.