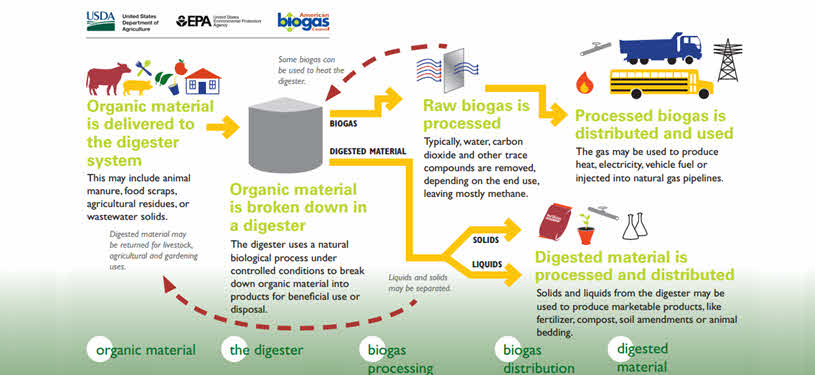

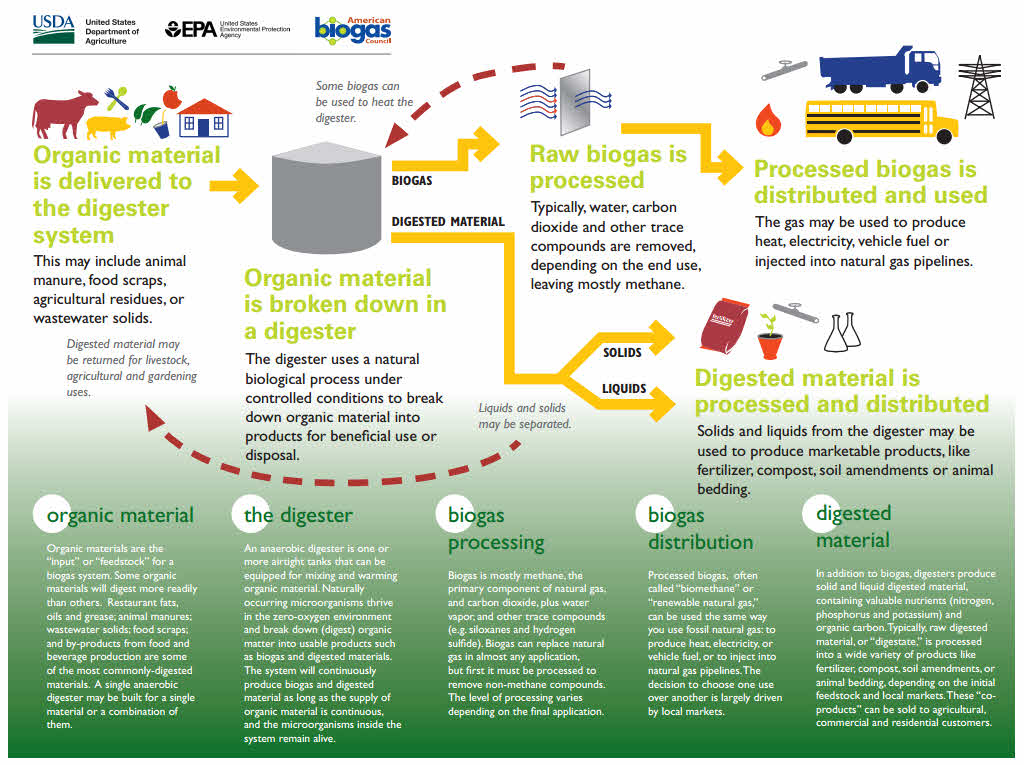

Anaerobic digestion is a series of biological processes in which microorganisms break down biodegradable material in the absence of oxygen. One of the end products is biogas, which is combusted to generate electricity and heat, or can be processed into renewable natural gas and transportation fuels. A range of anaerobic digestion technologies are converting livestock manure, municipal wastewater solids, food waste, high strength industrial waste water and residuals, fats, oils and grease (FOG), and various other organic waste streams like spent grains from distilleries or breweries into biogas. In addition, separated digested solids can be composted, utilized for dairy bedding, directly applied to cropland or converted into other products. Nutrients in the liquid stream are used in agriculture as fertilizer.

The Basics of a Biogas System

President Obama’s Biogas Opportunities Roadmap

This Biogas Opportunities Roadmap builds on progress made to date to identify voluntary actions that can be taken to reduce methane emissions through the use of biogas systems and outlines strategies to overcome barriers to a robust biogas industry in the United States. It supports the U.S. dairy industry’s voluntary 2008 goal to reduce its greenhouse gas emissions by 25% by 2020. This goal was a driver behind a partnership forged between the Dairy Industry and USDA in December 2009 and renewed in May 2013. As part of the 2013 renewal, the dairy industry also requested that USDA create a voluntary biogas roadmap to support this goal.

Biogas is a proven source of energy used in the United States and around the world for decades. The United States currently has more than 2,000 sites producing biogas. The Roadmap found that with the proper support, more than 11,000 additional biogas systems could be deployed in the United States. If fully realized, these biogas systems could produce enough energy to power more than 3 million American homes and reduce methane emissions equivalent to 4 to 54 million metric tons of greenhouse gas emissions in 2030, the annual emissions of between 800,000 and 11 million passenger vehicles.

Stay Informed: Sign up here for our Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Using Food Waste for Energy (Spent grain from distilleries and breweries)

USDA estimates that in 2010, approximately 133 billion pounds of food from U.S. retail food stores, restaurants, and homes went uneaten. This represents 31% of the 430 billion pounds of the available food supply at the retail and consumer levels in 2010, with retail-level losses accounting for 10% (43 billion pounds) and consumer-level losses for 21% (90 billion pounds) of the available food supply.

With the U.S. Food Waste Challenge, the U.S. Department of Agriculture (USDA) and the U.S. Environmental Protection Agency (EPA) have joined efforts to:

- Reduce food loss and waste,

- Recover wholesome food for human consumption, and

- Recycle food waste to other uses including animal feed, composting, and energy generation.

One objective of the U.S. Food Waste Challenge is to reduce the amount of food discarded to landfills. The EPA estimates that food waste is the single largest component of municipal solid waste going to landfills and that landfills are the third largest source of methane in the United States.

States, counties, and municipalities are helping to lead the way in reducing the amount of food waste discarded into landfills. Some are starting to mandate diversion of primarily commercial organics from landfills. Thus, more source-separated organics (SSO) are becoming available as feedstocks for biogas systems. Food production plants, universities, restaurants, hotels, and hospitals generate considerable volumes of organic wastes. Biogas systems can be designed and built specifically to process organic wastes on-site at these commercial facilities, or wastes from these sites can be transferred to serve as the feedstock for digesters at agricultural sites for improved food system resiliency. Some generators produce waste streams that are an economic liability to their operations but would be welcome financial additions to a biogas project, such as whey, residuals from bakery/brewery/winery, fats, oils and greases (FOG), due to the fact that these wastes produce high amounts of biogas.

The Anaerobic Digesters Process

The Biological Process

The digestion process begins with bacterial hydrolysis of the input materials in order to break down insoluble organic polymers such as carbohydrates and make them available for other bacteria. Acidogenic bacteria then convert the sugars and amino acids into carbon dioxide, hydrogen, ammonia, and organic acids. Acetogenic bacteria then convert these resulting organic acids into acetic acid, along with additional ammonia, hydrogen, and carbon dioxide. Finally, methanogens convert these products to methane and carbon dioxide.

Digester Technologies

Many different anaerobic digester systems are commercially available. The following is an overview based on organic waste stream type (manure, municipal wastewater treatment, industrial wastewater treatment and municipal solid waste): Manure: Anaerobic digestion systems for livestock manure operate to reduce methane emissions, odors, pathogens and weed seeds and produce biogas. They fall into four general categories:

- Covered anaerobic lagoon digester: Sealed with flexible cover, with methane recovered and piped to the combustion device. Some systems use a single cell for combined digestion and storage.

- Plug flow digester: Long, narrow concrete tank with a rigid or flexible cover. The tank is built partially or fully below grade to limit the demand for supplemental heat. Plug flow digesters are used at dairy operations that collect manure by scraping.

- Complete mix digester: Enclosed, heated tank with a mechanical, hydraulic, or gas mixing system. Complete mix digesters work best when there is some dilution of the excreted manure with water (e.g., milking center wastewater).

- Dry Digestion: Upright, silo-style digesters made of concrete and steel with rigid cover. Dry digesters operate at 20 to 42 percent total solids, which allows them to combine high dry matter manure and crop residuals with very dilute liquid manures or co-substrates.

Benefits of Anaerobic Digesters

- Result in cleaner air and water by destroying pathogens, controlling odor, stabilizing organics, reducing greenhouse gas emissions and providing opportunities for enhanced nutrient management

- Provide a source for distributed energy generation in rural areas

- Produce renewable energy to generate electricity and be used as a fuel for boilers or furnaces, offsetting fossil fuel use

- Yield pipeline quality gas or compressed natural gas that can be sold as a renewable fuel

- Provide a potential revenue source from the sale of energy, carbon credits or coproducts

- Improve relationships with neighbors due to reduced odor levels from manure storage and spreading

- Generate products for use on the farm, such as animal bedding and high quality fertilizer

How Biogas is Upgraded to Biomethane/Renewable Natural Gas

Captured biogas is transported via pipe from the digester, either directly to a gas use device or to a gas treatment system (e.g. for moisture or hydrogen sulfide removal). If the feedstocks contains high concentrations of sulfur and no steps are taken to prevent formation of hydrogen sulfide in the digester, then hydrogen sulfide is removed from the biogas to prevent corrosion of the combustion device or other downstream equipment.

Captured biogas can also be further upgraded by removing carbon dioxide, nitrogen and oxygen in order to meet the high purity and BTU requirements for pipeline injection or compressed biomethane vehicle fuel.

Conclusions of the Biogas Opportunities Roadmap Report

The Biogas Opportunites Roadmap prepared by the U.S. Department of Agriculture, U.S. Environmental Protection Agency, U.S. Department of Energy shows that biogas systems can offer significant improvements over traditional waste practices for organic material. While most organics other than manure find their way into landfills, companies and municipalities are looking to digesters for numerous environmental improvements. Biogas systems must be properly designed and managed to operate effectively and avoid creating new environmental problems.

Developing a viable biogas industry in the United States can boost the economy and provide a reliable, distributed source of renewable energy while reducing greenhouse gas emissions. Increasing production of biogas not only supports President Obama’s Climate Action Plan goal of cutting methane emissions, but it also increases energy independence and security.

Biogas systems are currently installed primarily to manage wastes, but can also improve profitability for operations through energy and co-product sales, nutrient recovery and avoided energy costs. These new revenue streams come along with the added benefits of reducing greenhouse gas emissions, improving water quality, and limiting odors. Although 2,000 sites operate today, more than 11,000 additional biogas systems could be employed to handle organic waste and produce energy and biogas system co-products. Biogas can play a critical role in the sustainability and viability of communities throughout the U.S.

Realizing the full potential for the biogas industry will require support from federal agencies, greater investment, expanded markets for biogas and biogas products, and increased research and development. The benefits of biogas systems are clear. The task ahead is to reduce barriers and promote financial opportunities to move forward in developing a robust biogas industry.

Resources

- U.S. Department of Agriculture, U.S. Environmental Protection Agency, U.S. Department of Energy: Biogas Opportunities Roadmap, The Benefits of Biogas Recovery, Benefits of Anaerobic Digesters, How Biogas is Upgraded to Biomethane/Renewable Natural Gas

- American Biogas Council: Overview of Biogas Process, The Basics of a Biogas System, What is Anaerobic Digestion?