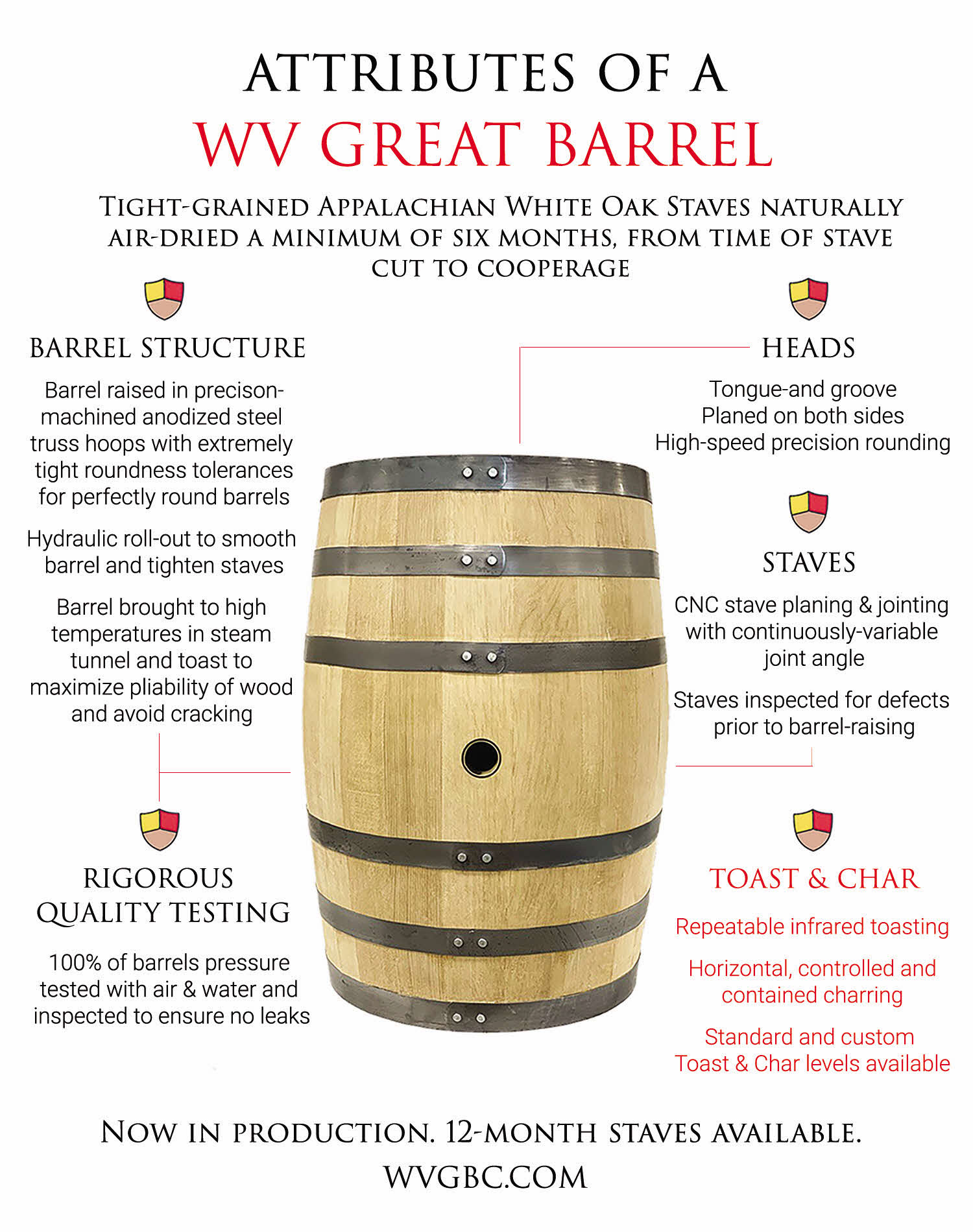

West Virginia Great Barrel Company is a new, state-of-the-art cooperage making 53-gallon barrels from tight-grained Appalachian White Oak that we cut and season for a minimum of six months at our mill in Monroe County, WV. We offer precision infrared toasting and horizontal gas char standard on every barrel.

We started with the desire to create jobs in a West Virginia town devastated by flood. Three years later, we are making custom barrels for award-winning craft distillers in our backyard and around the country, and for some of the most respected whisk(e)y brands around the world.

Up to 70% of a Whisky’s Flavor Comes from the Barrel

Distillers are looking for ways to innovate, make delicious whiskey, and engage their customers by focusing on the source material that goes into making their product, going to every length to ensure it is as special, regionally appropriate, and full of flavor as possible.

But no one is talking about wood in this way, even though it is widely understood that wood accounts for up to 70% of the flavor of aged spirit. Perhaps this is because up until now distillers have not had a choice about wood—not in the way they should. They have kind of been taking what they can get, taking cooperages at their word without having much information about what goes into making their barrels or what the potential variation is from one barrel to the next.

We want to change that. We’re doing everything we can to reduce that variation and to provide total transparency of our process and R&D to distillers. To that end, we are working with distillers to advance the research on toasting and charring of barrels. We employ Six Sigma practices to reduce variation in our manufacturing process. And we have our own state-of-the-art stave mill in Monroe County, WV, so we know exactly where our wood comes from.

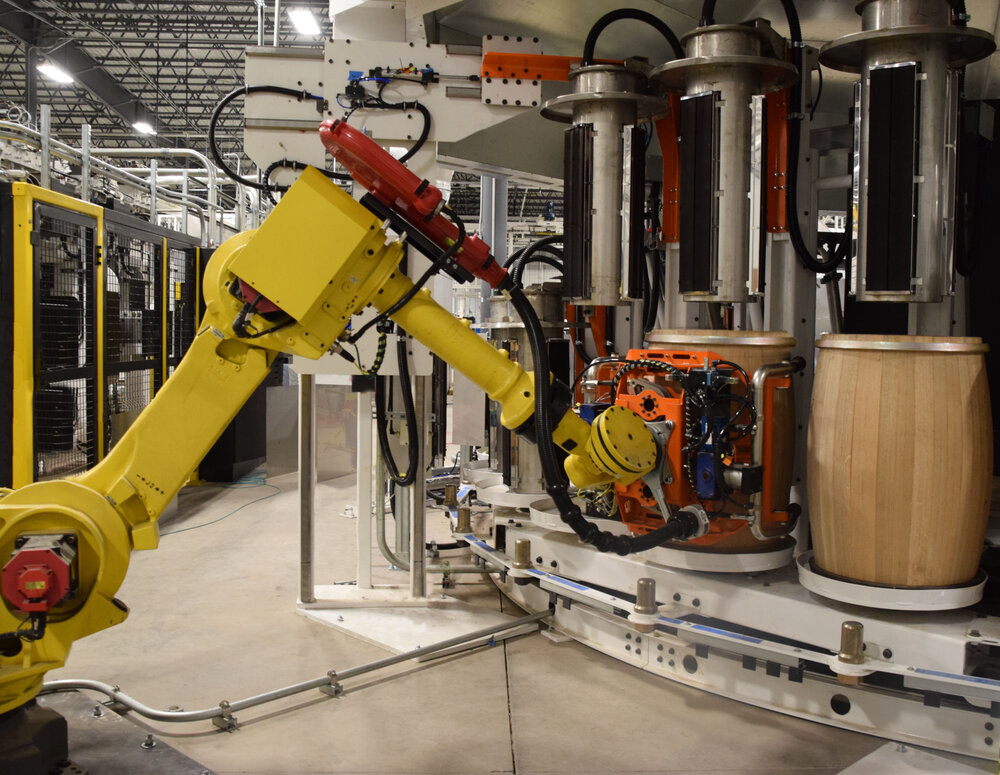

Reinventing the Modern Cooperage

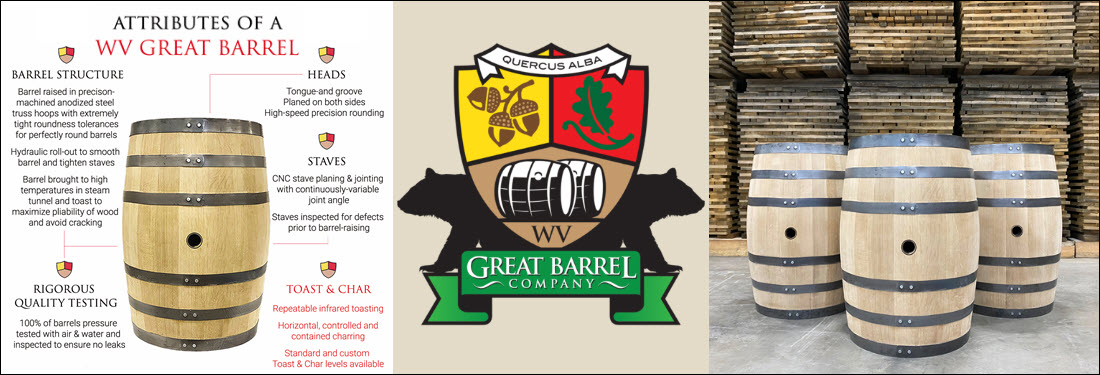

Our West Virginia cooperage is among the most advanced cooperages in the world. With our engineering partners, we’ve developed improvements to every stage of the barrel-making process. Every aspect of our process was engineered to safely, reliably and repeatedly produce barrels to the highest standards of performance and flavor development, while simultaneously allowing us to offer customized barrels to our customers.

Materials Matter. Wood Matters.

We know the provenance of every Appalachian White Oak log that comes to our stave mill and have relationships with loggers who sustainably harvest our wood. We hand-select logs with a tight grain because they contain a higher concentration of hemicellulose and lignin, where the primary flavor components are transformed when the barrel is properly toasted and charred.

Barrel staves and heading are quarter sawn, stacked and seasoned in our stave yard. The mill is ideally situated in a valley between two mountain ranges, where a natural wind tunnel provides a constant flow of air year-round. Seasoning in the elements helps to eliminate harsh, bitter tannins and other phenolic compounds.

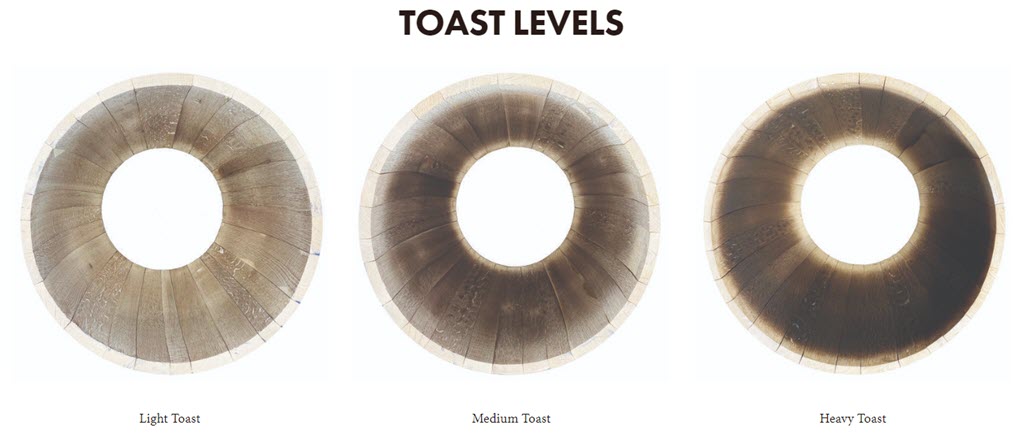

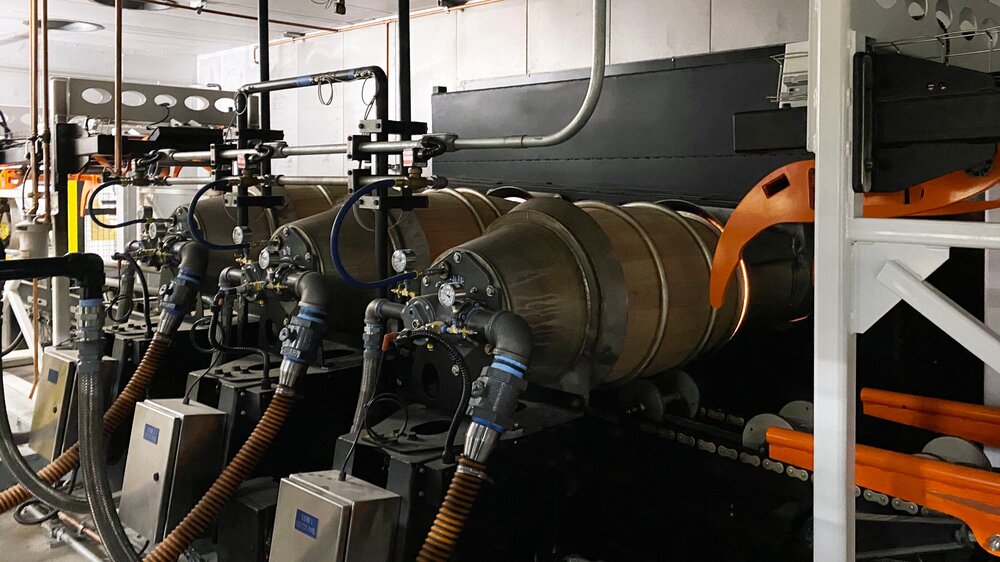

Infrared Toasting and Charring

Most distillers are familiar with a charred barrel, and they increasingly understand the positive impact that toasting a barrel prior to charring can have on maturation. Some cooperages “toast” barrels by lighting a fire on the ground and placing a barrel over it—a process laden with high cost and fraught with variation. Or they rely on the toast that naturally happens during char. At the West Virginia Great Barrel Company, we believe that a deliberate, controlled toast before char makes better whiskey, faster. Our infrared Carousel Toast delivers a consistent, controlled toast throughout the barrel and from one barrel to the next. We believe so strongly in the benefits of infrared toasting we’ve decided to offer it to all our customers free-of-charge.

Our horizontal gas char system is enclosed to regulate air flow. Barrels burn for a controlled amount of time before flames are quenched automatically at the target char level. This allows for a more consistent, repeatable char.

#1 CHAR – Less Woodiness

#2 CHAR – more Woodiness

#3 CHAR – The most common char—natural wood taste and scent, deeper colors, vanilla tones and caramelization

#4 CHAR – “Alligator Char,” a deep color, spicy flavor profile, with smoky, char flavor contrasted with sweeter notes

Custom Char – Available to all of our customers

Ready to Get Started?

Visit: West Virginia Great Barrel Company

Contact Cate Crabtree – Account Manager

Email: Cate.Crabtree@wvgbc.com

Phone: 304-520-0612