They say that bourbon whiskey gets 50% to 75% of its flavor and color from the oak barrel. We at Foeder Crafters of America believe you should not only finish your bourbon in oak but you should start it in oak as well with our foeder handmade American white oak fermentation barrels and vats.

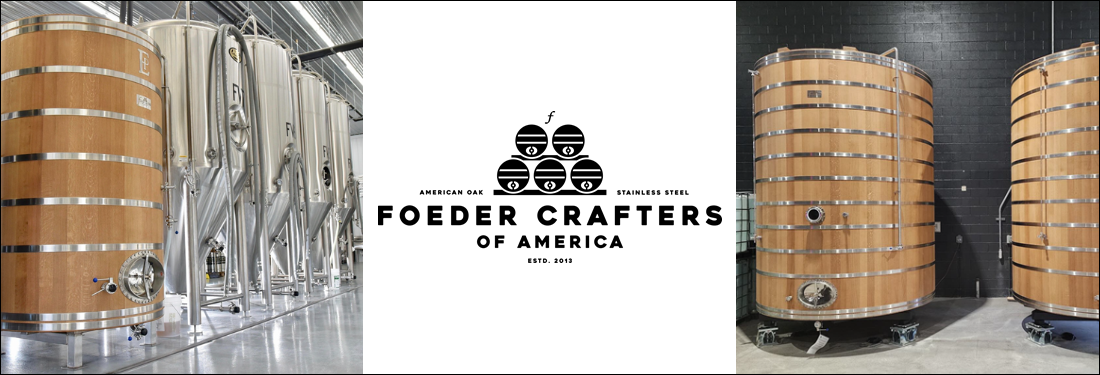

As America’s premier manufacturer of large-scale oak beverage tanks, we have helped hundreds of breweries, wineries, cideries, and distilleries grow their business.

Historically oak barrels were standard equipment, but over time stainless steel has largely replaced them. Utilizing oak in fermenting and maturing can provide your distilled spirits with complimentary flavors and add depth.

The level of tyloses in American white oak creates an incredibly dense, and hardy wood. Tyloses occurs during the process of sapwood turning into heartwood, thus creating the perfect wood for building airtight and leak-free tanks! In addition to superior tyloses, the composition of this species of oak, has a high amount of vanillin, lipids, and lactones. During aging American oak imparts a coconut and vanilla, spicy sweetness

We proudly utilize Missouri white oak. All our oak is sourced within a 100-mile radius of our shop. Once harvested, our oak is air dried for roughly 2 years before it enters the kiln to hit our target moisture percentage. This process ensures that the oak is free of any pests or infections and allows the oak to naturally dry, avoiding any checking or degradation that can occur if dried too quickly.

White Oak Tanks Tailored to Your Needs

At Foeder Crafters, every project is an opportunity to partner with our customers and create the best solution for their process and facility. Every foeder we build leaves our shop on time and 100% tested. We’re the easiest partner you’ll ever deal with.

While you’ll see our standard sizes shown here, we have built tanks as small as 500L and as large as 9,000 gallons. If you don’t see it, just ask. No matter the size or shape, our foeders offer several advantages over barrels:

- More consistent product – our foeders ship air-tight and have a high liquid-to-wood ratio, which allows only a very slow oxygen ingress that is easily monitored with the tasting valve. Having fewer, larger vessels means less blending of varying flavors and stages of maturity.

- Time and labor savings – product moves in and out through tri-clamp ports. No more racking, filling, dumping, and tasting multiple barrels.

- More efficient use of space – floor space is often at a premium in small production facilities. We can craft you a custom solution to maximize your use of your footprint.

- Aesthetics – let’s face it, foeders are just beautiful! Many of our vessels end up in an area that is customer-facing, which is the ultimate compliment to us.

How Foeder’s Crafts it’s Fermentation Tanks

We’re very proud of the thought and care we put into every foeder we build. Here is a short glimpse into how we do it.

- Slow Growth, Sustainable Forestry – Missouri is blessed with more white oaks (quercus alba) than any other state. Our climate and soil composition makes for trees that grow slowly and have perfect grain structure. There are over 15 million acres of hardwood forest in Missouri and the annual growth far exceeds the amount harvested, ensuring sustainability for future generations.

- Log Selection – After harvest, our sawmill sets aside its best logs specifically for Foeder Crafters – only about 3% make the cut. The logs are then sawed to our specifications and are set out to dry in the open air for at least two years. The harsh environment breaks down a lot of the tannins in the wood and mellows it in a way that a kiln cannot.

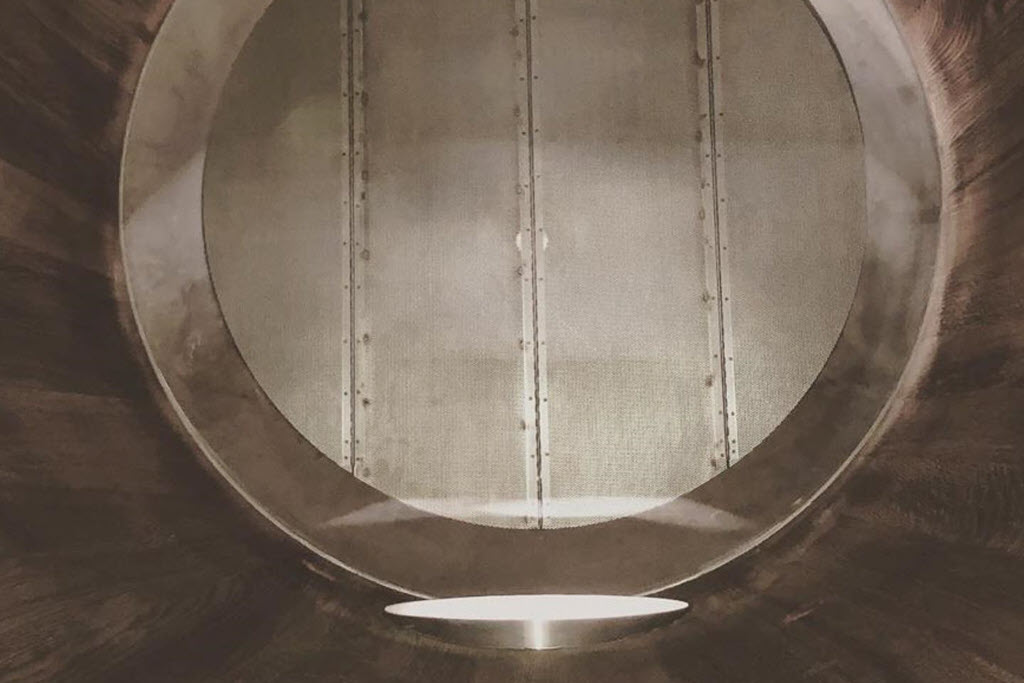

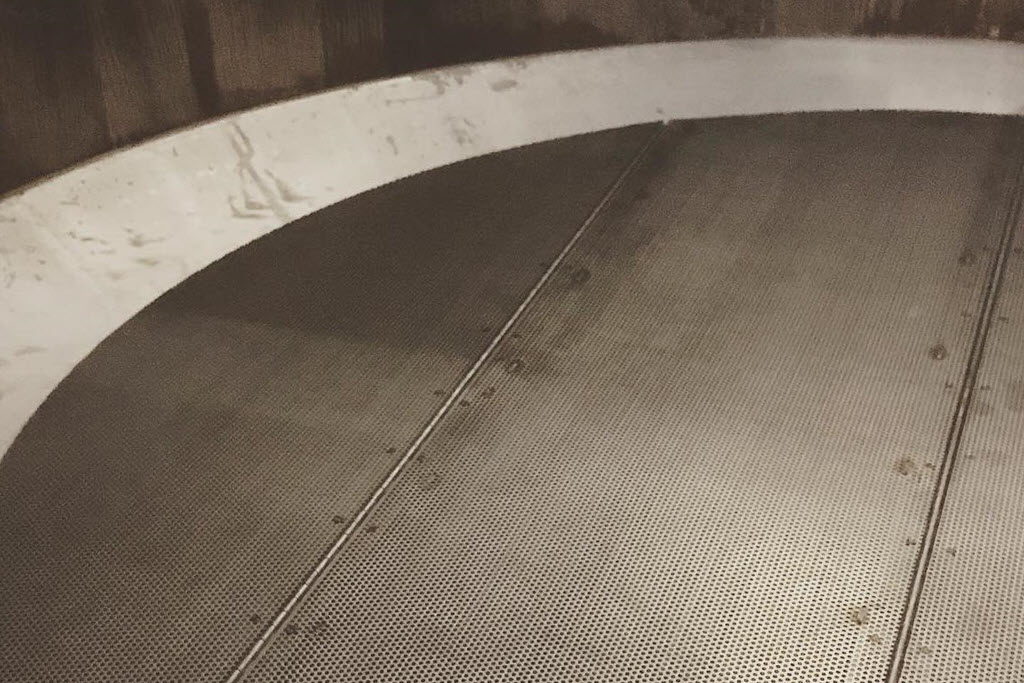

- Assembly – After every board is tested and tasted, the staves are pieced together. As shown above, our staves are finger-jointed on the side, which sets our foeders apart from the competition. These joints lock the staves into place (especially after hydration) and make the tank extremely stable and solid, but more importantly, air tight.

- Hydration and Testing – After the bands are welded into place, each foeder is steamed for at least 12 hours. This sanitizes and hydrates the wood, while also pulling out a majority of the tannins that are left. The foeders are then filled with water and left to sit for at least 3 days. This slowly completes the hydration and surfaces any issues that need to be fixed so we can deliver a leak-free tank.

- Finishing – The last stop in the shop is our finishing department. Each foeder receives a final sanding and a very light topcoat. This gives the wood a beautiful ‘pop’ and also a little bit of protection from inevitable splashes in its final home.

- Shipping and Installation – Whenever possible, we use our own driver for shipping and installation. The foeders arrive tarped on a flatbed trailer and are placed into their new home, stands assembled, and accessories installed. White glove treatment – all you provide is a forklift (and maybe an extra set of hands, in some cases).

Ready to Get Started? Let’s Talk.

Call 314-944-8800

Email FoederCrafters@gmail.com

Reach out to get a quote started. You can expect a response from a real person within an hour or two during normal business hours. We will help you figure out exactly what you need and how we can build it for you.