One thing that makes Maker’s Mark bourbon unique vs. many of the other heritage bourbon distilleries is they don’t wander too far from founder Bill Samuels, Sr’s. original taste vision. While other distilleries make two or three styles of bourbon, rye or a malted whiskey mash bill Maker’s Mark Distillery in Loretto, Kentucky continues to make one thing, a red winter wheat bourbon whiskey.

The way the family lore goes Bill, Sr, took the original 170 year old bourbon recipe his family had been making for nearly two centuries and he burned it. He chose to replace the hot rye bourbon with the sweet wheat bourbon that wouldn’t “blow your ears off”.

In working to keep the flavor profile consistent from year to year and bottle to bottle Maker’s Mark is one of the few distilleries that rotates their barrels. It’s a process that starts in August and wraps up around June of the next year.

As Maker’s Mark Director of Innovation Jane Bowie explains it, “Starting on August 1st we start rotating barrels. For example, with a seven-story warehouse the seventh story goes to the first, the sixth to the second, the fifth to the third and the fourth doesn’t move. In a six-story warehouse the sixth goes to first, the fifth to the second, the third and fourth don’t move. So, we do not rotate every single barrel, we rotate the majority. This year I think out team will rotate about 200,000 barrels.” That’s a lot of barrels, a lot of hands touching barrels and a lot of logistics to keep it all in order.

In 2010, Maker’s released Maker’s 46. It was a way for Bill Samuels, Jr. to leave his mark on the company before he retired. During that process that started it 2008 they experimented with more than 100 stave finishes. The process uses a fully matured, cask strength bourbon that is finished with 10 oak staves placed inside a barrel to come up with a unique taste profile. Experiment No. 46 is the one that Bill ended up liking and the name 46 stuck and Maker’s 46 was born.

With those 100+ tests in hand the process started what today is known as the ‘Wood Finishing Series’. The Series kicked off in 2019 with a five-year plan. 2019 brought RC-6, 2020 brought SE4 & PR5 and 2021 unexpectedly delivered two releases with FAE-01 in the spring followed by FAE-02 in the fall. The plan for 2022 always called for two releases and that brings us to our latest Day on the Trail adventure.

Maker’s Mark Distillery to Deliver Two ‘Wood Finishing Series’ Releases in 2022

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Every Wood Finishing Series comes with a taste vision. 2019 focused on the Maker’s yeast, 2020 focused on barrel seasoning, and 2021 focused on non-chill filtering. The 2022 releases are focused on extracting the flavors from the top and bottom floors of the barrel warehouse.

We got to learn about this year’s taste vision from Maker’s Director of Innovation Jane Bowie and Innovation Manager Beth Buckner while visiting the distillery. Their mad scientist lab is located in a picturesque building a few hundred feet from the distillery along a creek bed with flowing limestone water. Through the windows you can hear the sound of hammers and saws as workers are busy putting up dry stone bridges and walkways along the creek that will one-day be walking trails for distillery visitors.

-

Save

“We are entering year four of the Wood Finishing Series,” explained Bowie. “We set it up as a story telling series. All the learnings we’ve had coming out of [Maker’s] 46 and Private Select. Realizing people love this limited space, they love new things. Whiskey is fun right. So why not use all the learnings we’ve had and do something that gives people a fun new expression of Maker’s Mark every year. We set these up, as Bill Samuels, Jr., would say, ‘Let’s talk to ourselves in the geekiest way possible.’ So, every year there’s been a different taste goal. We probably start out each project about 18 months before it actually hits the market.

“We [Jane and Beth] start along with Denny [Potter, Master Distiller] and Rob [Samuels, Managing Director of Maker’s Mark]. The four of us sit down and talk about the story we want to tell and the taste goals that should come out of that.

“We planned five years of this project before we ever started. This was the year we were always going to do two whiskies. Last year when we got into the thick of it, we couldn’t agree as a team, so we ended up doing two whiskies to kind of make peace with each other and go on.”

2022 to Celebrate Barrel Rotation

“This was always two because we want to celebrate barrel rotation this year,” said Bowie. “The goal was, as you know we rotate our barrels halfway through their lives at Maker’s Mark, everything goes into the warehouse in the top half of the warehouse. After three Kentucky summers, August 1st every year we start rotating.”

The reason we’ve stuck to this method said Bowie is, “We only make one whiskey. For us, that lifecycle is everything. Now, does a six-one taste the same as a five-two or a four-three, ‘No’, there is nuance. But are they as different as tasting a 10 year old that has lived in one place its whole life vs. a 10 year old that’s been rotated? They are much, much closer from a taste profile.”

Getting Out the Wood Goodies – Extraction, Reaction and Oxidation

“How we think about it is, the whole goal of the first three years at the top [of the warehouse] is all about extraction. The last three years at the bottom is all about reaction. It’s about getting as much of the wood out as you can in the first three years to really dive into that red layer to get those wood goodies. And then you are moving it to a less extreme environment to let it come together and oxidize, react and mature.

“So when we sat down to talk about these taste goals, and I think what’s been fun about this… is when we started this we started quite close in and kind of, I don’t know if safe is the right word but when you look at 2019 and 2020 they were really familiar taste profiles compared to Maker’s. And I think what we’re excited about is as this goes on its kind of, and people get more familiar, we’re allowed to get further outside the spectrum a little bit and people are hopefully trusting us to go into some new tastes of flavor that they don’t always expect from Maker’s Mark.”

“The whiskies are becoming more polarizing. We are usually pretty evenly divided in the lab. Denny and Beth are usually on the same team and I’m over here. And Rob is like the Dad and thinks it’s all really good. He will never pick a favorite.”

2022 Taste Vision 1: Extraction from the Top of the Warehouse

“This year, the first taste vision is the top of the warehouse,” explains Buckner. “We were looking for toasty and nutty and very caramel. All the things you would expect to extract from the wood. Big, bold and really fun.”

Bowie added, “When you walk into the top of the warehouse the smell is different. It’s a dryer smell and heat because of how the climate is up there. When we thought about this whiskey we actually thought about those smells you get at the top of the warehouse. It is dry spice, and it is a woody barn yard smell but in a toasty way. We have never done a toasty Maker’s Mark…but it’s never really been a part of Maker’s so this is a little outside of normal role.”

2022 Taste Vision 2: Reaction from the Bottom of the Warehouse

“The second one is about the bottom floor,” said Buckner. “It’s all about reaction so its deeper, it’s darker, you are going to get more of those dark fruit notes like chocolate but also think like leather and tobacco in those camps as well.”

“When you think about maturation, we always think about four things,” added Bowie. “You are adding the addition. What you are extracting is an actual addition. The char layer acts as a subtraction as well. And then its oxidation, that’s why white oak is so magical, is its air porous. Think about what oxidation provides and then reaction. You need the reaction time to let it develop and become, it’s not just extraction, it’s all those things.

“So, the first release is really about extraction and then the second really is about some of those fruity esthery darker tobacco notes that only time can give you in the barrel.”

How the Wood Finishing Process Works

The process always starts with fully matured cask strength Maker’s Mark. Maker’s is typically aged five to seven years. The first three summers are spent on the top floors of the warehouse before they are rotated to the lower floors. Rather than experimenting with 53-gallon sized barrels of bourbon they start out with barrel soaks in 1 liter bottles.

“We do bench top samples. It’s a bottle soak process that represents a barrel,” said Bowie. “These are going to taste really different than anything you are going to get in a few months when we release these whiskies. We cannot do hundreds of full barrel experiments it would be wasteful and irresponsible.”

“We start with five pieces of very small wood. Those are pieces of a stave just cut smaller,” added Buckner. “It represents the same exact process, but we’ve made it smaller where it will fit in a liter bottle. Then we put the liter bottle in our walk-in cooler that is the same temperature and humidity as the [whiskey] cellar to mimic the process [of Maker’s 46 and Private Select]. And we start each one, there is enough [pieces of wood] for three different soaks, and we start them a week behind each other so at all times we have three different aging weeks going. And the first one we let go all the way to nine to 12 weeks.

-

Save

“What this really allows us to do is if we know we like something at week six, we have two more week sixes coming behind so we can validate with the second or third set.

“Once we do two to three rounds of really consistently nailing the flavor, we’ll then go to a single barrel prototype. From there we feel pretty confident,” said Bowie.

“We do all the staves blind. Because you find you start naturally building biases. I have a favorite oven and I tend to be more French Oak than American Oak on a lot of these finishes. So, we keep it all blind so there is no bias of ‘Oh, it’s French Oak in a convention at this toast level here’s what I think I know what it will taste like.’ We don’t actually know until the very end and then Andrew [Wiehebrink, Head of Research and Development at Independent Stave Company ] will say ‘Ok, here’s what it was.’ And then there will be things we find that don’t fit the goals of this project and we’ll say, ‘Will you save this stave for us?’ We have proprietary ownership for all the wood that we use with them. There will be things out of here where we say ‘Oh, I really like that, it’s not right for this project but let’s put it in the cookie jar and remember and maybe we’ll go back to it for a different project.’

“In the final days, we take samples and drink it at home in a different environment that’s not so analytical. Just because it tastes good in the lab, how does it translate when I’m sitting with my husband after dinner having a drink. That’s a different experience.”

How Do They Keep it All Straight?

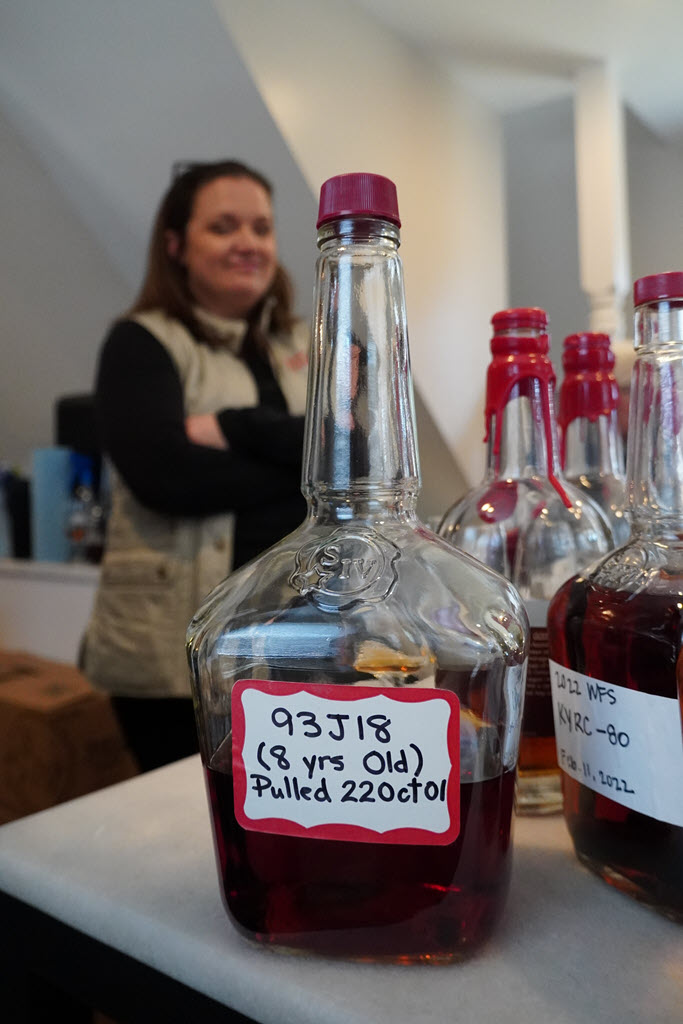

As you can see in the photograph there are a lot of samples and dates to keep track of. The day we visited they were about a year into this latest project for the 2022 release.

The first number is randomly assigned to each stave. The wood and finishing process used for the sample is only known to Wiehebrink. The second number after the dash is the week number since the soak began.

-

Save

At first the wood floats in the bottle but as it absorbs the whiskey it starts to sink into the whiskey. Take a closer look at the position of the wood and the color of the bourbon for the newer soak vs. the one that has been aged for multiple weeks. Again, these bottles are all kept in a chilled and humidity-controlled room inside the lab. When the Maker’s 46 program first started, they could only mature it inside a rickhouse during cool winter and spring months. Once summer hit it was simply too hot inside the rickhouse. The solution was to build Whiskey Cellar where they now mature 46, Private Select and the Wood Finishing barrels year-round.

There were definitely taste differences between the younger and older bottle soaks. Some got better with age while others went a bit too far. This year’s dual release is still a work in progress, but the experimenting continues.

Once the final selections are made full size barrels of fully matured Maker’s will have 10 of whatever the winning stave is placed inside the barrel. Those barrels will then be aged inside the Whiskey Cellar for however many weeks make up the winning batch.

And finally, since this is the year for the twofer, we got to try two special treats. The first was a 21-year-old bottle of an 8-year-old Maker’s that was distilled in 1993 and bottled in 2001. And the second was a sludge bottle or the more friendly titled infinity bottle that was filled with a little of everything that was also sitting in the 49 degree chilled fridge.

We’ll keep you posted with progress and what ends up in each of this year’s releases as they are announced.

Learn more about Maker’s Mark Distillery.

View all Bardstown/Nelson County Distilleries.

View all Kentucky Distilleries.

View all U.S. Distilleries.

———— GET OUR FREE NEWSLETTER ————

————— FEATURED SUPPLIERS —————

View all Featured Suppliers.

———— FEATURED DISTILLERIES ————

View all Featured Distilleries.

———— MOST POPULAR ARTICLES ————

- Federal Judge Rules Ban on Home-Distilling is…

-

Save

-

- The Kentucky Bourbon Trail Celebrates its 25th…

![The Kentucky Bourbon Trail Celebrates its 25th Anniversary and Announces Major Changes on the Way [Full Video] Kentucky Bourbon Trail - Celebrating 25 Years of the Kentucky Bourbon Trail](https://www.distillerytrail.com/wp-content/uploads/2024/06/Kentucky-Bourbon-Trail-Celebrating-25-Years-of-the-Kentucky-Bourbon-Trail-Cover-300x138.jpg)

-

Save

-

- Introducing the 2024 ‘Kentucky Bourbon Hall of Fame’…

-

Save

-

- Nebraska Governor Proposes Plan to Implement 287%…

-

Save

-

- Whiskey House of Kentucky Kicks Off Distilling…

![Whiskey House of Kentucky Kicks Off Distilling Operations at 'The Most Sophisticated Distillery in the U.S.' [VIDEO] Whiskey House of Kentucky - Opening Day July 1, 2024](https://www.distillerytrail.com/wp-content/uploads/2024/07/Whiskey-House-of-Kentucky-Opening-Day-July-1-2024-Cover-Wide-1-300x78.jpg)

-

Save

-

- Woodford Reserve Revives Historic 1812 Elijah Pepper…

-

Save

-

- Buffalo Trace Distillery Announces Colonel E.H.…

-

Save

-

- Maker’s Mark Distillery Announces ‘The Heart…

![Maker’s Mark Distillery Announces ‘The Heart Release’ – The 1st in a 5-Year Wood Finishing Series [VIDEO] Maker's Mark Distillery - 2024 Wood Finishing Series, The Heart Release Bottle](https://www.distillerytrail.com/wp-content/uploads/2024/06/Makers-Mark-Distillery-2024-Wood-Finishing-Series-The-Heart-Release-Bottle-Cover-1-300x138.jpg)

-

Save

-

- Heaven Hill Distillery Launches a New Bourbon,…

-

Save

-

- Eastern Light Distilling Celebrates Groundbreaking…

![Eastern Light Distilling Celebrates Groundbreaking on New $143.7 Million Eastern Kentucky Distillery [Renderings] Eastern Light Distilling - Groundbreaking July 3, 2024](https://www.distillerytrail.com/wp-content/uploads/2024/07/Eastern-Light-Distilling-Groundbreaking-July-3-2024-Cover-Wide-300x78.jpg)

-

Save

-

———— DISTILLERY LOCATIONS ————

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

-

Save

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Instagram and Twitter.