When you think about a distillery the first thing most people picture is a patina colored copper pot still with steam rolling off and the smell of fermenting grains in the air. There’s that and old Grand Pappy’s stories of running his old homemade still out in the third holler after you drive three miles down a dirt road across the rickety bridge past where the old Oak tree used to be then up the hill a bit. There, right there, that’s where Grand Pappy used to make his shine. Ah, the good ol’ days!

As the laws in the U.S. have changed and it’s easier to get licensed to start one’s own legal distillery the country has seen a boom in craft spirits distillery startups. According to Michael Kinstlick, CEO of Coppersea Distilling by the end of 2016 there will be more than 1,000 producing craft distilleries in the U.S. Kinstlick also predicts that number will double in the next five years. One thing every one of those distilleries needs is a still of some sort. What kind of still, what material will be used and the size of that still is in the eye or flavor palate of the beholder. That’s where Vendome Copper & Brass Works comes into the picture. Vendome is one of the best known still manufacturers in the world today. They make custom handmade stills, columns, tanks, fermenters and more that get delivered all over the country from Florida to Alaska as well as all over the world to places like Guatemala, Canada and yes, even good old Ireland.

I recently had an opportunity to get a behind the scenes tour of their Louisville, Kentucky headquarters and shop with 4th generation family member Vice President, Rob Sherman. He took me on a tour that covered a city block. An area where this family has been building and servicing products for the distillery, brewery, pharmaceutical, dairy, chemical, food and confectionery industries for more than 100 years.

Makers

the quality of design and work shown in something made by hand; artistry.

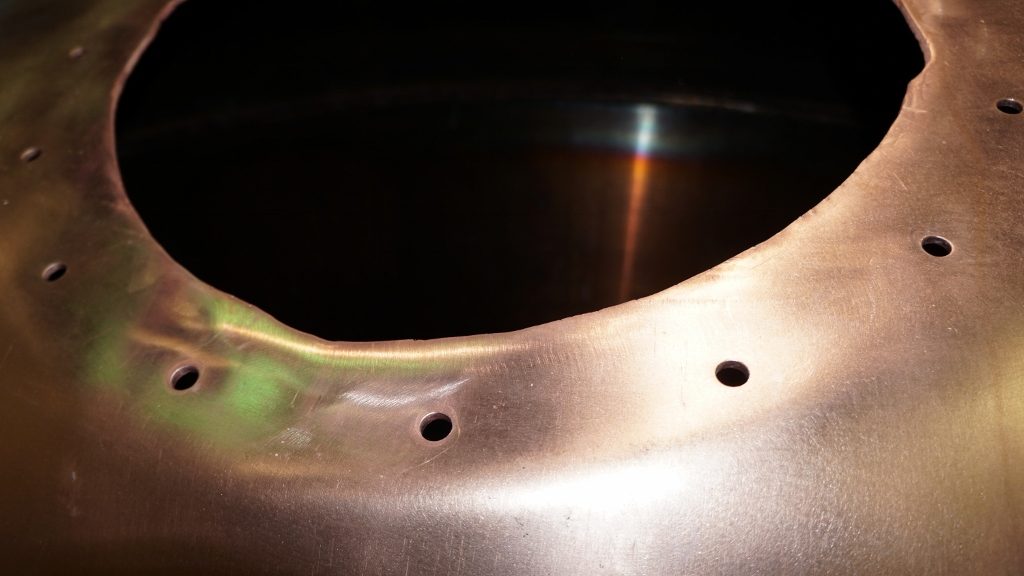

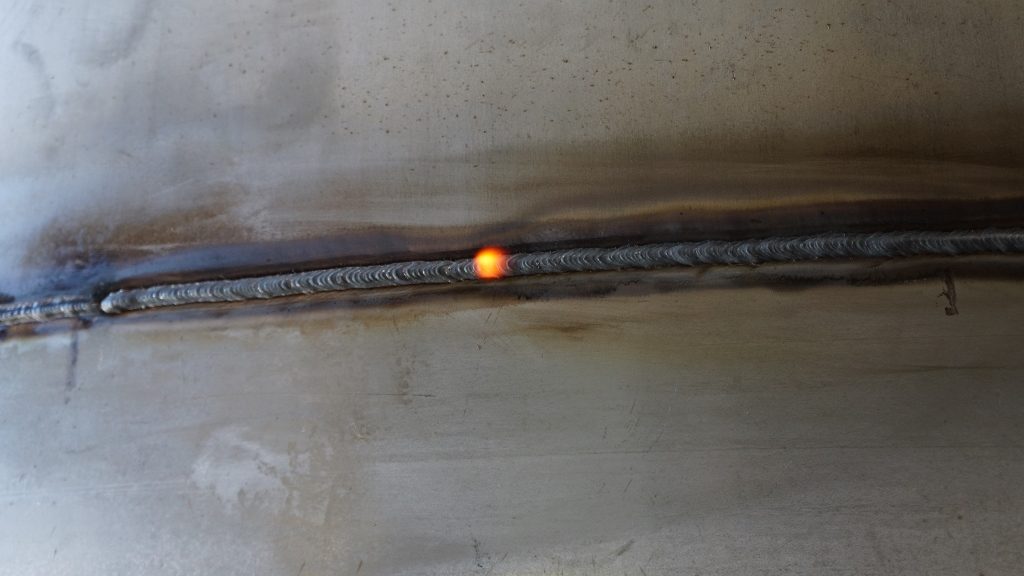

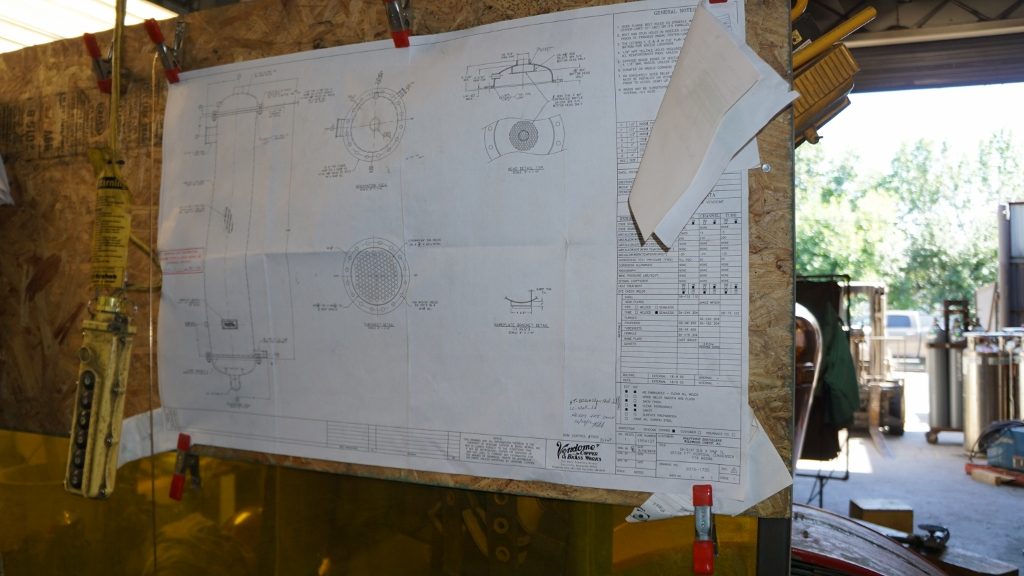

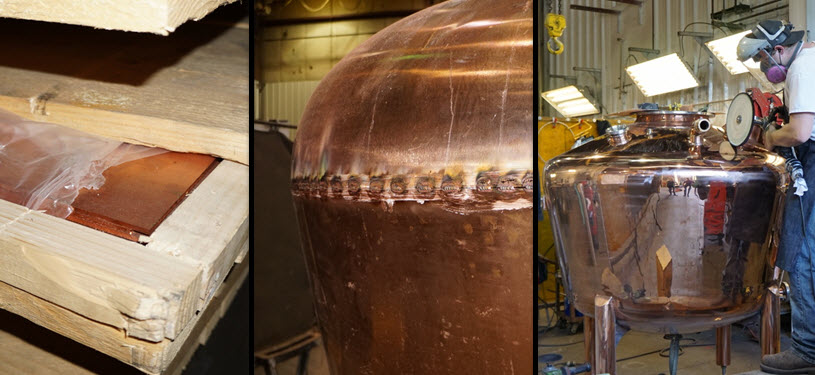

It’s a busy place with about 75 craftsman working two shifts, six days a week. As soon as you walk in the shop you are welcomed with the site, sounds and smells of metal being cut, hammered, welded, torched, drilled, ground, stretched and polished. There are lots of modern tools and machines but as you look closer at the rolling tool carts you’ll see that some of these tools haven’t changed much from the company’s founding in 1911.

Dance Like No One is Watching

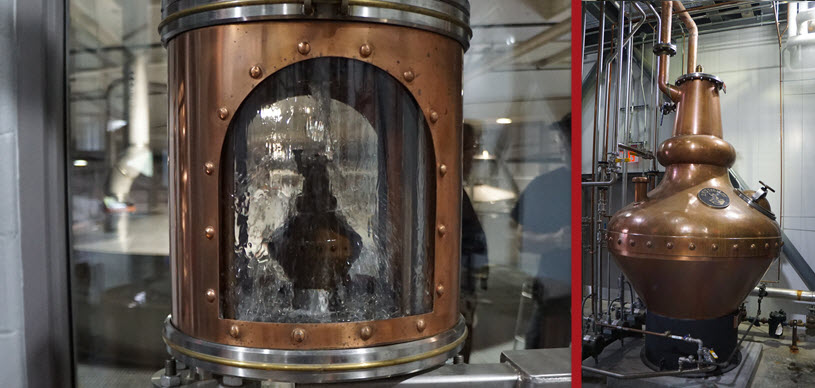

This often overused phrase is what hit me the other day when I spent a “Day on the Trail” at one of Vendome’s customers. I had an opportunity to tour the Michter’s Distillery and saw some of Vendome’s work first hand. On the right side of the photo you can see Michter’s Copper Pot Still Doubler. Take a look at the left side of the photo and you’ll see a miniature version of the copper pot still inside the Michter’s Spirits Box. The Michter’s Distillery is not open to the public so for the most part, the spirits box you see here will not be seen by the public. That’s craftsmanship.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Here’s a photo tour of a day in the shop. You’ll see a variety of copper and stainless steel stills, columns, tanks, cookers, condensers, molds and more. Come by on another day and you might see a fleet of a dozen flat bed trucks getting ready to travel 1,000 plus miles out West. Walk by tours of Vendome Copper & Brass Works are available exclusively through Mint Julep Tours here.

Take a look and get inspired. Chances are, if you can dream it, they can make it.

Related Stories

Why Are Stills Made of Copper?

Vendome Copper & Brass Works: A Century of Custom Handmade Stills

A Day in the Vendome Copper & Brass Works Shop

Please help to support Distillery Trail. Like us on Facebook and Follow us on Twitter.

Podcast: Play in new window | Download

Subscribe: Google Podcasts | RSS