The National Historic Site that is Buffalo Trace Distillery in Frankfort, Kentucky has been making bourbon whiskey for more than two centuries now. Because of their popularity, the bourbon, rye and wheat whiskies coming off these stills and aging in the Buffalo Trace warehouses are often allocated or just downright impossible to find.

In an effort to catch up with demand the distillery has been on a $1.2 billion construction boom for the last nine years. To date those efforts have resulted in an increase in whiskey making capacity at the distillery by a whopping 50%. Though that sounds like a lot, in the case of Buffalo Trace there are still fans waiting in long lines to get a chance to purchase some of their premium whiskey products.

Click any arrow above to learn more.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Buffalo Trace to Double Production Capacity by Year End

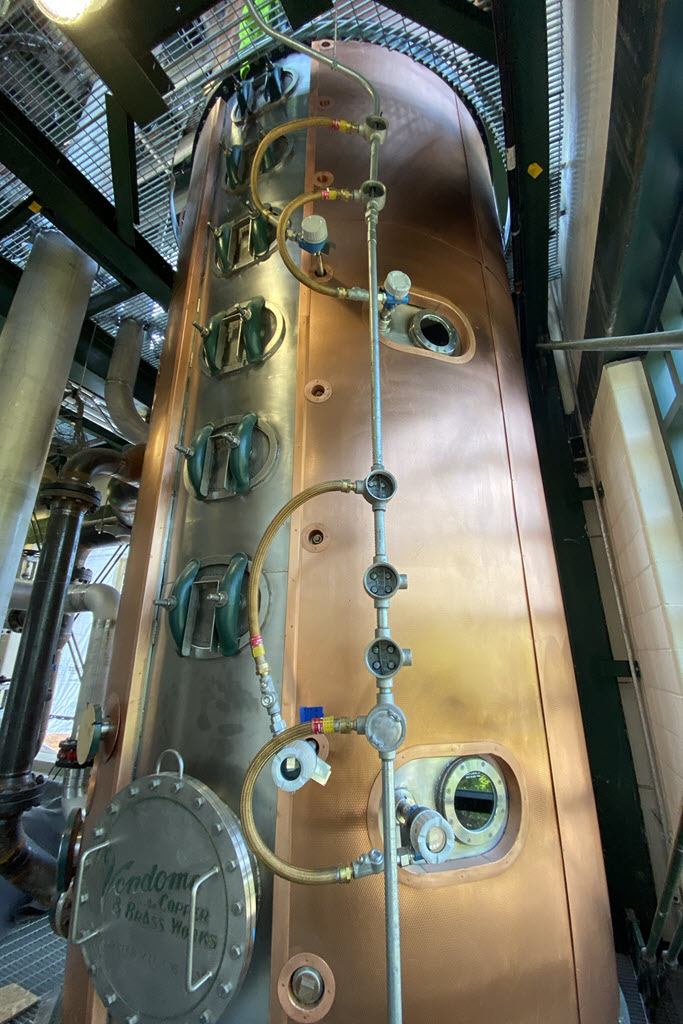

By the end of 2022, production at the distillery is expected to double when their new 40’ x 84” Vendome Copper & Brass Works column still finally comes online. To give you can idea of how big this is, the second still which required a second still house (see the photos below) is located adjacent to Buffalo Trace’s existing 1930s still house and contains a duplicate still to the existing one. Assuming all things go to plan the new column will be online by December 2022 with a capacity of producing 60,000 gallons of new whiskey per day. Combined, the two mirrored columns will have total capacity of 120,000 gallons per day. Annualized (in a perfect world) that would near 43,800,000 gallons of spirits per year. If you are a barrel person, that breaks down into more than 2,264 barrels per day. (These are back of the napkin estimates based on 60,000 gallons/still/day.) Wow!

The $1.2 billion expansion encompasses all operations at Buffalo Trace Distillery, starting with a new distribution center and bottling operation in 2015 and 2019. More recently, the Distillery added 14 new barrel warehouses, 12 additional fermenters, additional cookers, a new cooling system and tripled the size of its visitor center. In 2022, Buffalo Trace’s additional dry house for drying out the spent grains, hammer mill for grinding the grains to prepare them for cooking and fermentation, additional still house doubling distillation capacity and wastewater treatment plant have been constructed are all expected to be operational by the end of this year.

-

Save

“We’re finishing the electrical work in the new still house now, and then will move into commissioning it for test runs in the next few weeks. If all goes as planned, we will start production before the end of this year. We are excited to double our distillation capacity so we can bring more bourbons to our fans,” said Master Distiller Harlen Wheatley.

The wastewater treatment plant will process 1.2 million gallons of water per day. “It’s rare to see this much money invested in a standalone, sophisticated wastewater treatment plant. I am excited to see its start up because it truly demonstrates Buffalo Trace Distillery’s commitment to protecting the Commonwealth’s water,” said President of Aqua Utility Services, Steve Tolliver, Buffalo Trace Distillery’s regional wastewater operator.

The treatment plant will be comprised of a moving bed biofilm reactor, allowing wastewater to be treated efficiently and maintain water quality standards. Wastewater will be treated and disinfected so it’s clean enough to release into the Penitentiary Branch, which leads to the Kentucky River. As you can see from the photos, the distillery sits right on the Kentucky River.

-

Save

“We appreciate our fan’s patience as we’ve been laying down the foundation to produce more American Whiskey than we ever have before,” said Sara Saunders, vice president, Buffalo Trace Distillery.

“We are still catching up to consumer demand and though our bourbons can be hard to find at times, more is coming! When our new still starts early next year we will double our production…. And then we wait for it to age because one thing we will not do is cut any quality corners by lowering proof or age. We are committed to maintaining the highest quality whiskey at fair prices.”

Increased Bourbon Production Means New Jobs

In addition to increased production, the expansion has added 200 production-focused jobs at Buffalo Trace Distillery over the past four years. With the continued capacity increases, there will be up to 50 more jobs added in the coming few years.

Patience, patience, patience. Keep in mind, all those barrels have to age before they ever hit the store shelves. It will still be several years before the words “Buffalo Trace” and “Allocated” are not said in every other sentence, Cheers!

Learn more about Buffalo Trace Distillery.

View all Frankfort Area Distilleries.

View all Kentucky Distilleries.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Instagram and Twitter.