Long before there was bourbon, there was beer. And beer, a locally brewed Belgian style table beer, is what Jane Bowie and Denny Potter chose to celebrate the groundbreaking for their new distillery.

In August of 2022 Maker’s Mark Distillery Head of Blending Jane Bowie and Master Distiller Denny Potter announced they were leaving the historic Loretto, Kentucky distillery. A couple months later, the dynamic duo announced they would be starting J & D Distilling Company, a new distillery that would be built in Springfield, Washington County, Kentucky about 18 miles from Bardstown, the Bourbon Capital of the World.

A Groundbreaking and ‘Field Party’

Everyone does their groundbreaking a little differently. Some dress up in suits, have shiny shovels to toss some dirt, get a handful of state or local politicians to speak and then raise a glass of someone else’s liquid to toast their new endeavor. In the case of Jane and Denny that just wasn’t their style. They decided to have a Field Party to celebrate their new distillery. The party included food, games, free hats, a VIP port-a-potty air-conditioned trailer with running water, a beer truck with a dozen taps, and about 200 of their closest friends.

“The thought of dressing up, it wasn’t us,” said Bowie. “Awkwardly putting a shovel in the dirt, let’s just have a keg party.” Potter agreed and added, “Let’s just throw a party.”

Introducing the ‘Potter Jane Distilling Company’

-

Save

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

With hundreds of their friends coming to the Field Party they knew they had to have a name but what?

“The J & D Distilling Co. was a place holder,” explained Bowie. “We had to have something legally filed so we could be a business. As we were building out our financials, we had a tab on a spreadsheet named J & D. And that name kept being repeated so that ended up being the placeholder name.”

“We knew that’s not what we wanted it to be. We were not comfortable with having our names on it,” added Potter. “We wanted the whiskey and the operation to speak for itself. We went through so many names.”

“Everything is taken,” exclaimed Bowie. “We would find a name and then the lawyers would be like, ‘here are 75,000 risks with that’. And finally, we were back to our names.”

“They [the lawyers] basically said your best shot of getting something trademarked would be your names,” said Potter. As the groundbreaking approached, they knew they had to pick a name, at least a name for the distillery and brand names could come later.

“We talked about using first names, last names seem so formal. So finally, we were like Potter Jane Distilling Company,” said Bowie. “This is the first time we’ve told this story. Once we started saying it, we liked it. Once we saw the first visual, we loved it.

“We’ll work on brand names later. I think the liquid has to come first and then we can build a brand that feels true to the liquid. The two things need to go together. It’s going to be fun.”

Related Story – Watch Jane Bowie and Denny Potter Share the Inside Scoop of the New ‘Potter Jane Distilling Company’ [VIDEO]

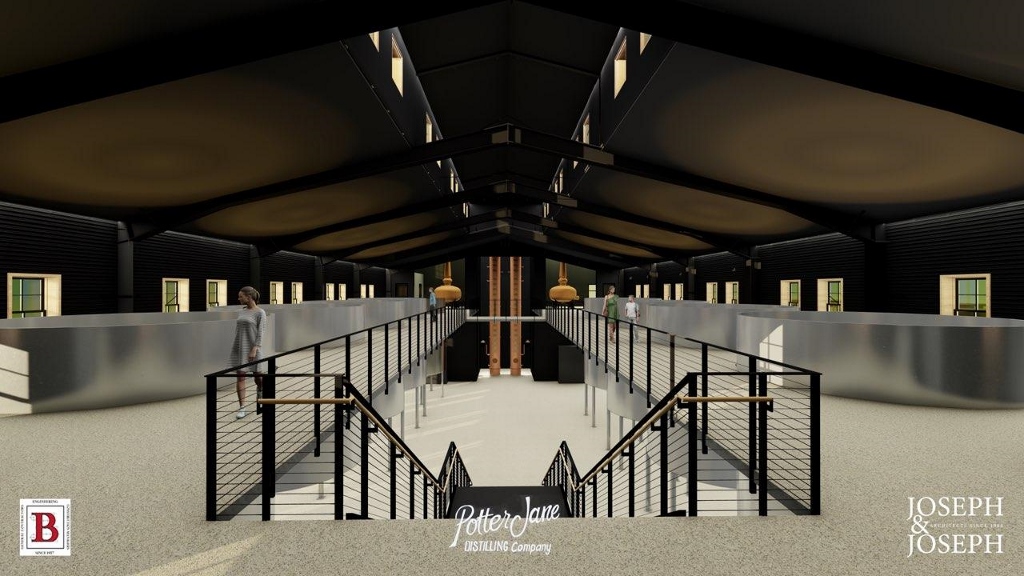

A Straight Shot Linear Distillery Design

“We’ve called it a shotgun distillery. Having worked at different distilleries and being friends for so long, the way we wanted the process to flow we knew, we could have told you the moment we started the project,” Bowie said. “This is something we’ve talked about for years. Having worked in operations in many old buildings things often go where they go but if you had your druthers, you would do it a different way.

“We wanted the process to flow in order. We wanted it to be a straight shot. We think it is simple and beautiful. There is something beautiful about a simplistic operation. The less time your mash spends in a pipe the less risk there is for contamination. We wanted a single straight through shot, kind of like a shotgun house. The grains are coming in on one end and it’s going in order. You have the grainery, to the cookers, to the fermenters, to the stills, to cisterns and out. It all flows straight down the building.”

“In distilleries you always want to avoid bends in pipes,” said Potter. “You don’t want 90s, you want to avoid 45s if you can but if you can have straight runs of pipe, it’s your best chance of avoiding bacterial contamination, which is the number one issue you can have in a distillery for making off whiskey. It really made it easier to design.

“From day one, we were all about process. When we walked into that first project meeting, we knew we wanted a 36” column, we want 10,000-gallon mash tubs, we want 20,000-gallon fermentation tanks, here is the temperature range, here is the barrel entry proof, so we need this many cistern tanks… From a functionality point of view, we’ve always looked at this from the eyes of the operator.”

What Will the Distillery Look Like?

“From a visitor perspective, we built the distillery with our employees being our first customers and visitors will be our second. We had come from a place were when form and function work together well it is magical… There is something nice to be able to give a visitor a chronological grain to barrel tour that goes straight through. We love it. And from a design perspective it has those two towers as bookends on the distillery. The grain tower is on one end and the distillery tower is on the other end and the entire operation is in one room,” said Bowie.

“Our goal is to make really great bourbon that we want to drink.” Jane Bowie

What’s Under the Hood of the Distillery?

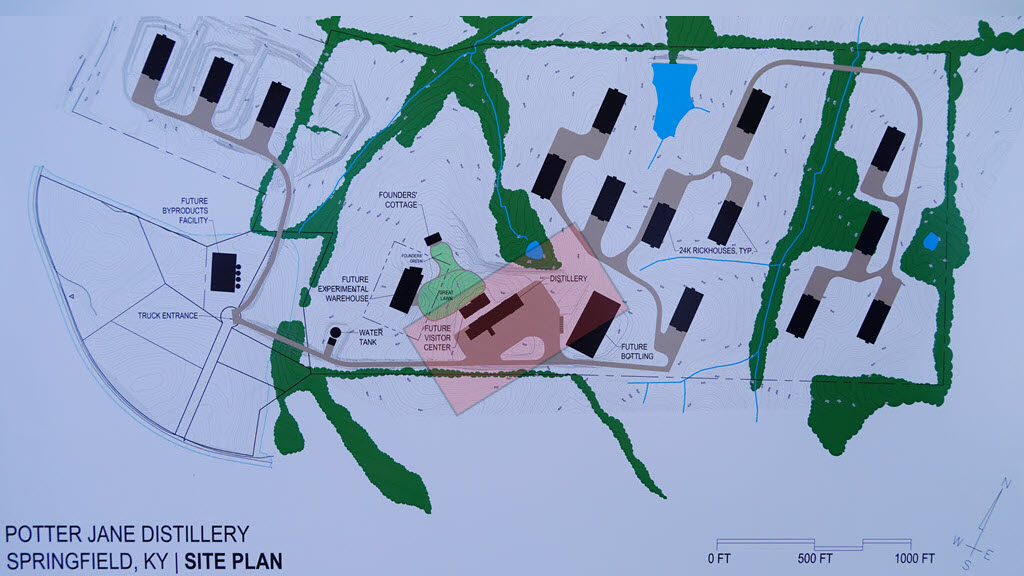

When the state of Kentucky first announced the distillery, it was a $30 million project. That number has since grown to $50 million. The distillery will sit on 153 rolling acres in a Washington County industrial park that is already built for water, sewers, electricity, and natural gas.

And just to put an exclamation point on the rolling acres the duo shared a story about the first time they toured the property with their construction company.

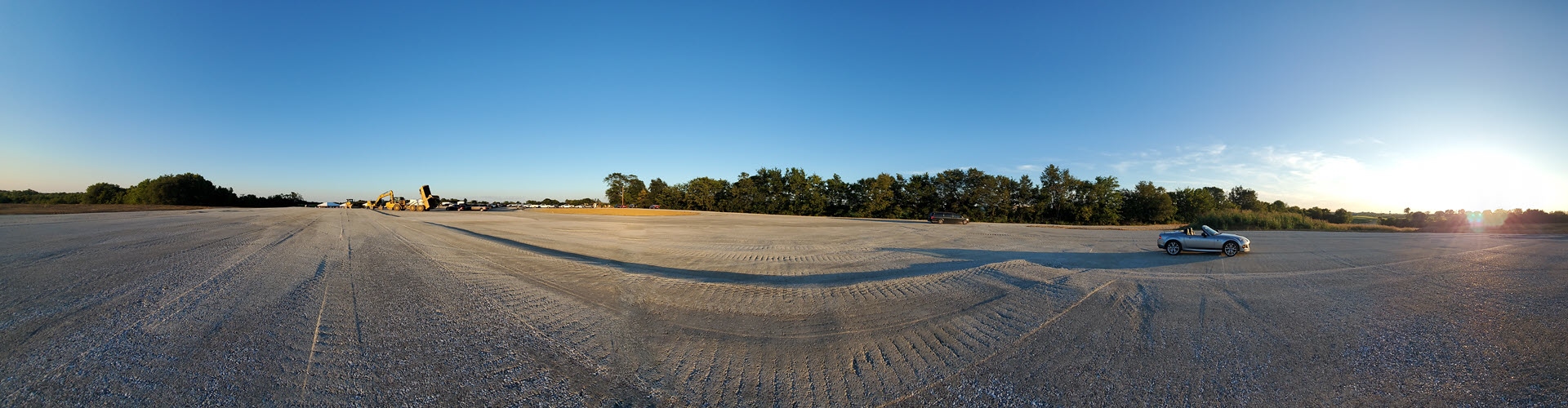

“The property has already changed drastically. Six months ago, there wasn’t a flat piece of land on the whole property. When we first showed the property to Donald Blincoe (President of Buzick Construction) he just rolled his eyes with a ‘really guys?’. They created the plateau [where the distillery will sit].”

The shotgun design of the distillery will allow everything to flow from one end to the other during whiskey production. Using the straight shot distillery path grains will come in and start their journey in a roller mill leading to a pair of 10,000-gallon cookers, then on to 10 20,000-gallon open top fermentation tanks, and a beer well leading to a 36” Vendome Copper & Brass Works copper column still. There is room for two stills but the initial plan is to start with one. From there the distillate will go to a 500-gallon doubler and then on to barreling. The distillery will be running six days a week and produce about 45,000 barrels of Kentucky bourbon and rye whiskey per year. With all those barrels, they’ll allocate some of the production capacity for contract distillation.

Rickhouses to Follow the Sun

Those barrels will be stored in 24,000-barrel rickhouses. The plan is to start building two right away for a total of 15 on the property. Since they are starting with a 153-acre blank slate the goal is to build the rickhouses in a north-south direction. This will allow for maximum exposure as the sun travels from east to west throughout the day. On a side note, here is an interesting story by Andrew Wiehebrink of Independent Stave Company about the effects of heat and humidity in a rickhouse. Wiehebrink notes that the temperature value doesn’t have as great of an effect on the extraction curve as does the temperature swing within a given time period. In other words, it’s not how hot it gets in the warehouse, it’s more to do with a combination of how fast the temperature fluctuates and the degree of fluctuation as it pushes the liquid in and out of the staves.

Timeline of the New Distillery

The gravel has been put in place and rolled for the distillery foundation. Rebar is being placed and concrete is expected to be poured over the next couple of weeks. The plan is to be fully operational and making whiskey by the beginning of 2025.

“Everything is tracking for January 2025 operational date,” said Potter. If they don’t kill each other first (their words, not ours).

Cheers to new beginnings!

Related Stories

– Maker’s Mark Master Distiller Denny Potter and Head of Blending Jane Bowie are Leaving the Distillery for a New Venture – August 2022

– Former Maker’s Mark Head of Blending Jane Bowie and Master Distiller Denny Potter Announce ‘J & D Distilling’ – October 2022

Learn more about Potter Jane Distilling Company.

View all Bardstown / Nelson County Distilleries.

View all Kentucky Distilleries.

View all U.S. Distilleries.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Most Popular

- Love & Whiskey: The Remarkable True Story of…

- Buffalo Trace Distillery Announces Opening Day for…

- EOSYS Group Helps Create a Bottling Line ‘Double…

- Bardstown Festival Raffling Off ‘Bourbon Unobtainium…

- Bourbon Crusaders 2023 Charity Auction Shatters…

- RD1 Spirits Celebrates Groundbreaking of New…

- A New Day is Dawning in Eastern Kentucky as Startup…

- Maker’s Mark Distillery Celebrates Women’s History…

- The Sweet Moment of Truth Has Arrived: After 9 Years…

- Bardstown Bourbon Co. Creates Buzz with Top-Secret…

A panoramic view of the future home to the Potter Jane Distilling Company.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Instagram and Twitter.