Whiskey barrel warehouses come in a variety of different styles and configurations. Palletized, dunnage, traditional rick, and all kinds of variations within. In Kentucky, the most common style you see while traveling across the state is traditional rick warehouses otherwise known as a rick house.

Rick houses vary in design and generally range between a couple thousand barrels to well over fifty thousand barrels. Most are going to be multi story buildings and generally store three barrels high on each floor. Some producers prefer to build single story rick houses and go up six barrels on that single floor. Each are going to have advantages and disadvantages when it comes to things like cost efficiency, safety, and flavor development.

Related Story – Part 2 (3-year Results)

Independent Stave Co. Barrel Warehouse Experiment – Year-3 Results of a 4-Year Study on Heat & Humidity by Floor

Each Floor Ages Whiskey a Little Different

The interesting thing about this method of storage is that each floor ages the whiskey a little bit differently due to the environmental differences that are unique to each floor. The lower floors will have a cool and humid environment and as we go up each floor, the temperature gets warmer, and the humidity gets lower. In some of the taller rick houses, the yearly average temperature difference between the top and bottom floors can be as high as 25%.

Independent Stave Company felt this was something worth exploring a little deeper so two years ago we began an experiment to study the effects of these temperature differences between each floor. To do this, we installed temperatures and humidity sensors on each floor of a five-story rick house and filled thirty identical barrels full of whiskey and placed them evenly across all levels of the rick house (six barrels for each floor). The warehouse is fifteen barrels high (three high on each floor) and holds approximately 10,000 barrels at full capacity. The warehouse is located atop a small plateau about 650 feet above sea level in Bardstown, Kentucky. The data outlined below is from year one of the experiment.

First let’s take a look at the average temperatures for each floor. This is displayed in table 1 below.

Barrel Warehouse Ave. Temperature & Humidity by Floor over 12-Months

| Floor 1 | Floor 2 | Floor 3 | Floor 4 | Floor 5 | |

|---|---|---|---|---|---|

| Ave Temp | 53.7° | 55.4° | 56.9° | 58.3° | 61° |

| High Temp | 83.8° | 85.5° | 86.6° | 89.8° | 104.6° |

| Low Temp | 24.6° | 26.2° | 28.1° | 28.9° | 28.1° |

| Ave Relative Humidity | 75 | 72.8 | 70.5 | 67.6 | 61.7 |

| High RH | 91.2 | 91.2 | 91.2 | 91.8 | 89.2 |

| Low RH | 39.4 | 37.9 | 38.3 | 35 | 28.8 |

As predicted, the average yearly temperature increases, and relative humidity decreases with each ascending level in the rick house. The humidity and temperature differences between floors were not as significant as we have seen in taller and higher capacity rick houses. As stated above, the nine story rick houses can have up to a 25% percent average yearly temperature difference between the top and bottom floor.

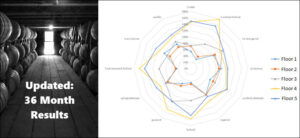

Extraction Curve Per Rickhouse by Floor Over 1-Year – Amplitude

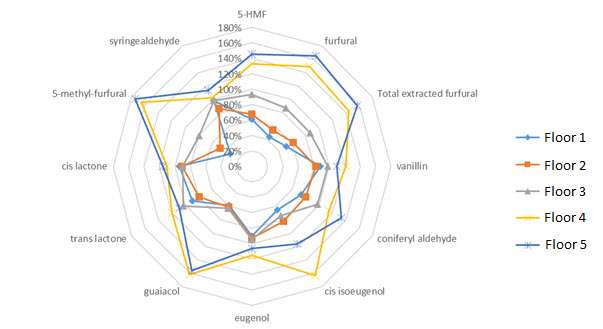

Let’s compare these values to the extraction curves for the whiskey being aged on each floor and see if there are any obvious correlations.

Figure 1. Chemical data for 12-month whiskey samples.

The first thing I noticed is that the extraction curves are not proportional to the yearly average temperature values with respect to each floor. This is an important point to make. This is because the temperature value doesn’t have as great of an effect on the extraction curve as does the temperature swing within a given time period. In other words, it’s not how hot it gets in the warehouse, it’s more to do with a combination of how fast the temperature fluctuates and the degree of fluctuation. In graphical terms, this is referred to as amplitude or pk-pk value in some cases.

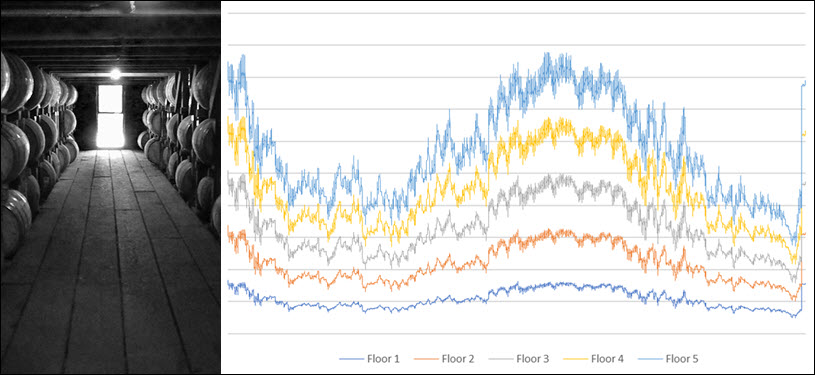

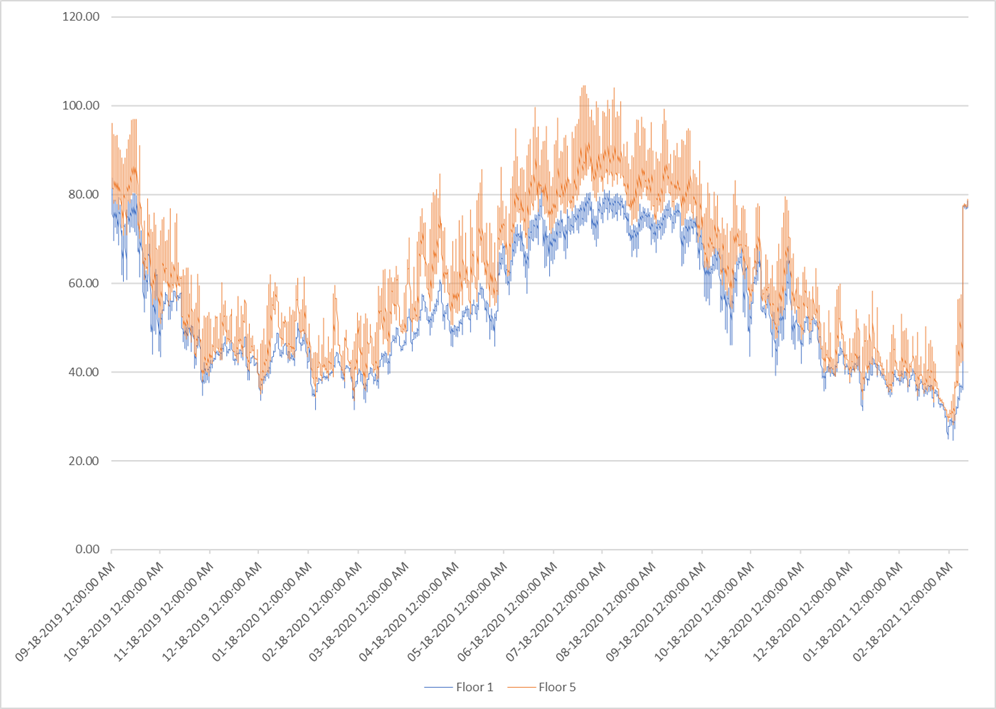

Looking at figure 2, we can see just how significant the difference in temperature swing is between the top and bottom floors.

Temperature Swing Between Top and Bottom Floors

Figure 2. Temperature curves for floors 1 and 5.

The temperature patterns across both floors are essentially identical but amplitude values are quite different especially during the summer months.

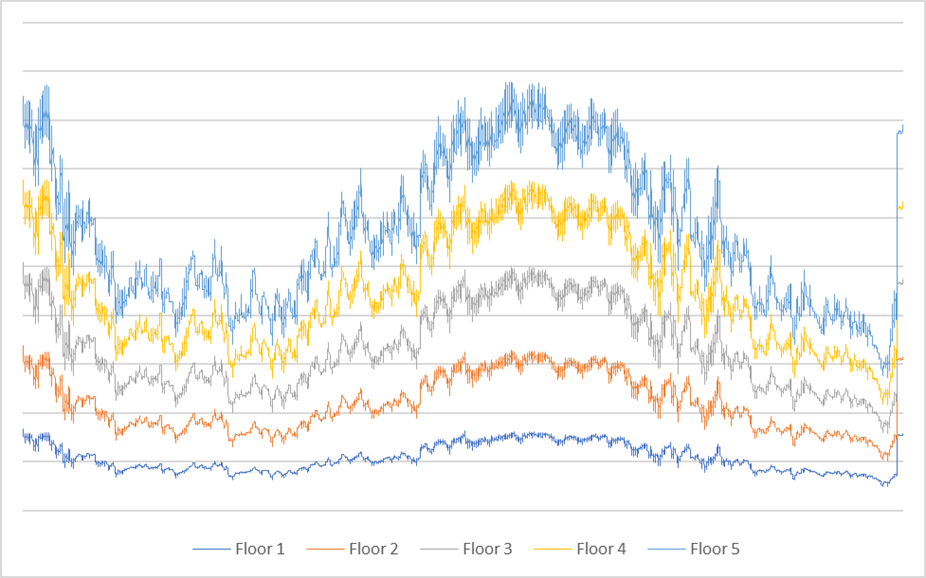

Figure 3 displays the temperature curves for each floor in the warehouse over one year. Please note the y-values are not an accurate representation of the temperature value.

Figure 3. Temperature curves for Floors 1 through 5.

When we start comparing the difference in swing for each floor’s temperature curve, the extraction curves presented in figure 1 start making a little more sense. As with figure 1, floors one through three are quite similar with floor three having a slight boost over floors one and two. Floors four and five showing a significant increase over the bottom three floors.

The data from this experiment isn’t particularly groundbreaking but it does confirm some understood theories with respect to aging in traditional rick house style warehouses.

- Average temperature rises as we go higher in the rick house

- Average humidity drops as we go higher in the rick house

- Temperature has an effect on the extraction of barrel aged spirits

- Temperature swing has a greater effect on the extraction of barrel aged spirits

- Temperature swing is more severe as we go higher in the rick house

Points 1-3 are very basic but points 4 and 5 might be a little surprising for most people and perhaps useful to those who are doing some temperature-controlled aging. This experiment is scheduled to last four years and I look forward to seeing what the next three years of data look like.

What is BrandScape? BrandScape is a way for product and service suppliers to talk directly to our audience. If you would like to learn more about BrandScape, please email Info@DistilleryTrail.com.

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Instagram and Twitter.