Jack Daniel’s has been distilling and bottling Whiskey for over 100 years, achieving a level of storied success company founder, Jasper Newton (Jack Daniel), could only have imagined. With a continuously growing demand, historically reliable bottling methods needed to change. Working with EOSYS Group – Controls & Software, the Jack Daniel’s bottling team set out to identify a Manufacturing Operations Management (MOM) platform that would provide them with the scalability and flexibility to move their organization forward today, while also allowing for growth in the years ahead. Here is the story of how EOSYS implemented TrakSYS at the Jack Daniel’s bottling facility in Lynchburg, Tennessee.

Challenges

- Disparate information in disparate systems

- Lack of real-time communication

- Lack of real-time KPIs

- Minimal insight into individual line

- performance and quality

- Needing to implement a system without

- disrupting production

- Needing to implement a system that would be easily adopted and utilized by operators

Goals

- Reduce bottling lines downtime

- Reduce administrative work and paperwork

- Automate data retrieval

- Enable real-time communications with

- factual data

- Gain access to real-time, credible, and

- transparent KPIs

- Meet QMS compliance

Why TrakSYS?

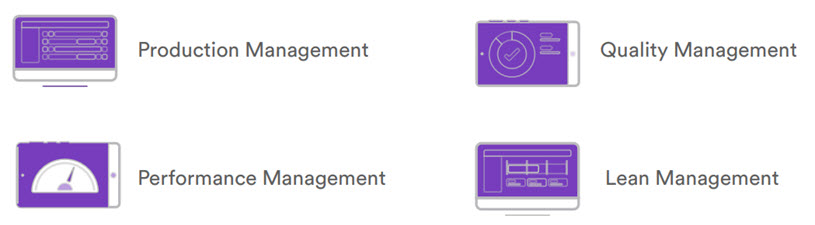

TrakSYS was the ideal platform when it came to meeting the initial needs of capturing OEE and reducing the paper footprint on the Jack Daniel’s bottling lines. As a unified MOM platform, TrakSYS offered the Jack Daniel’s team a comprehensive set of solutions that would not only meet their operational goals, but also provide solutions that promoted operator fluency and engagement. Once TrakSYS was implemented, the Jack Daniel’s team rolled out the platform to a pilot line, then set about commissioning the rest of the bottling lines onsite.

Key TrakSYS Features

“We never got that warm fuzzy feeling like “THIS IS IT” with any of the systems except one: TrakSYS.”

Jennifer Crabtree, Maintenance Manager – Jack Daniel’s Bottling

Solution Overview

TrakSYS has become Jack Daniel’s system of record for measuring the OEE of their seven production lines.

EOSYS implemented customized features like Multi-event Acknowledgement and Broadcast Notifications using TrakSYS tools to expand the existing functionality. With the Multi-event Acknowledgement and Grouped Events, operators were able to group events based on a few configurable variables, and enter downtime reasons for multiple occurrences, all at the same time.

“I’ve had more employee-initiated OEE conversations with operators over the past 3 months than I’ve had in the last 4 years combined!”

Adam Carlton, Operations Manager – Jack Daniel’s Bottling

Tasks were utilized for Quality Inspections and improving the paper-reduction initiative at Jack Daniel’s. All inline inspections that are documented have been migrated to TrakSYS, enabling more streamlined reporting and improving Quality Assurance.

Tasks that require a specific completion frequency have been configured to trigger automatically. The Broadcast Notification feature allows leadership to send messages to all bottling lines, or individual lines.

Teams utilize “cockpit pages,” which require acknowledgment, thereby ensuring a majority of associates see pertinent notes. Dispatch is displayed across dashboards at the head of each line, which has proven valuable for dispersing time-sensitive information across the site.

Line operators were engaged throughout the entire design process to promote user adoption and fluency. During design, strategic team leads provided feedback regarding how TrakSYS may have been adding work to the operators. This proved to be critical through commissioning, as the team leaders trained the operators to use TrakSYS. With their initial input already included as part of the implementation, user adoption of the system was very successful throughout every line rollout.

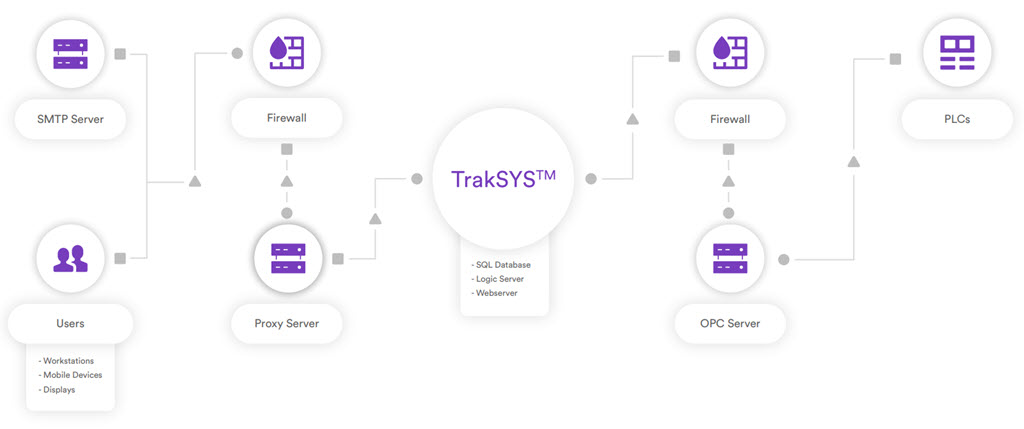

Solution Architecture

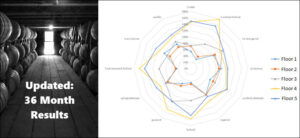

Results

Reduced downtime on bottling lines by 2.5%

- Gained access to real-time data that informed and enabled rapid communication amongst staff and departments

Reduced administrative labor and paperwork

- Gained access to real-time KPIs

- Exceeded QMS compliance standards

About EOSYS Group Distillery Controls & Software

Founded in 1991 to provide turnkey system integration services for manufacturing facilities, EOSYS has built its business by providing best-in-class integration services to manufacturers across North America. From its headquarters just outside of Nashville, Tennessee and its three regional offices, EOSYS specializes in industrial controls, manufacturing information systems, panel fabrication and installation, ICS cyber security, and OT network architecture services. Visit the website at www.eosysgroup.com to learn more about how EOSYS can help with your industrial digital transformation and TrakSYS integration.

About Parsec

Utilizing their 30 years of experience in manufacturing, Parsec created TrakSYS™: a best-in-class operations management software application and solution platform designed to significantly improve manufacturing operations. TrakSYS aggregates data from multiple sources to deliver real-time, actionable intelligence that helps manufacturers to reduce production costs, decrease lead time, and improve profitability. TrakSYS is deployed at thousands of factories, in over 100 different countries.

Contact EOSYS Group for Your Distillery Project

John Volz | John.Volz@EosysGroup.com | 615-355-7200

EOSYS, 140 Weakley Lane, Smyrna, Tennessee 37167

What is BrandScape? BrandScape is a way for product and service suppliers to talk directly to our audience. If you would like to learn more about BrandScape, please email Info@DistilleryTrail.com.