The Brooks Fields family has been supplying high quality grains to distilleries since the 1960s. The family roots grow deep in the heartland of America’s grain growing area. The operation is now lead by second generation grain merchant Erica Fields. For many years now Brooks Grain, named after Erica’s father, has been headquartered in Louisville, Kentucky. Being in the heart of bourbon country Brooks Grain is well known in the industry as a provider of grains to many of the world’s oldest and largest distilleries.

Ordering grains by the barge, trainload or truckload is an everyday occurrence for Brooks Grain and their partner Consolidate Grain & Barge (CBG). Their massive silos reach into the sky like skyscrapers and can be seen from miles around. The large scale works great for large distilleries that order multiple truckloads of grain each day. Over the 10 years as the number of craft distilleries started to grow they started providing bags of milled grains to craft spirits distilleries by outsourcing milling and bagging. Back about three years ago decided it was time to move the milling and bagging of grains in house. A year after that they started construction on an 80′ by 80′ by 50′ tall building.

Click the video below to watch the ribbon cutting ceremony.

Ribbon Cutting Grand Opening Celebration of Milling & Bagging Facility

The new state of the art milling and bagging operation designed to meet the needs of craft spirits distilleries recently celebrated its grand opening. The new facility provides a variety of grains including distillers corn, rye, wheat and malted barley. The same grains that go to the big distillers are now available to craft spirits distillers in smaller more manageable sizes.

Patience Fields Representative Brooks Grain, Matt Nidlinger Group Facility Manager Consolidated Grain and Barge, Stephan Schuermans Business Development Sangati Berga, Raelynn Atwell Castlen Steel, Mike Hucker Regional GM Consolidated Grain and Barge, Drew Kice President Kice Industries, Erica Fields President Brooks Grain, Tori Doughty Craft Distillery Sales Brooks Grain, Nathan Brunner Facility Manager Consolidated Grain and Barge and Nick Nessan Bulk Grain Merchandiser Brooks Grain (L to R).

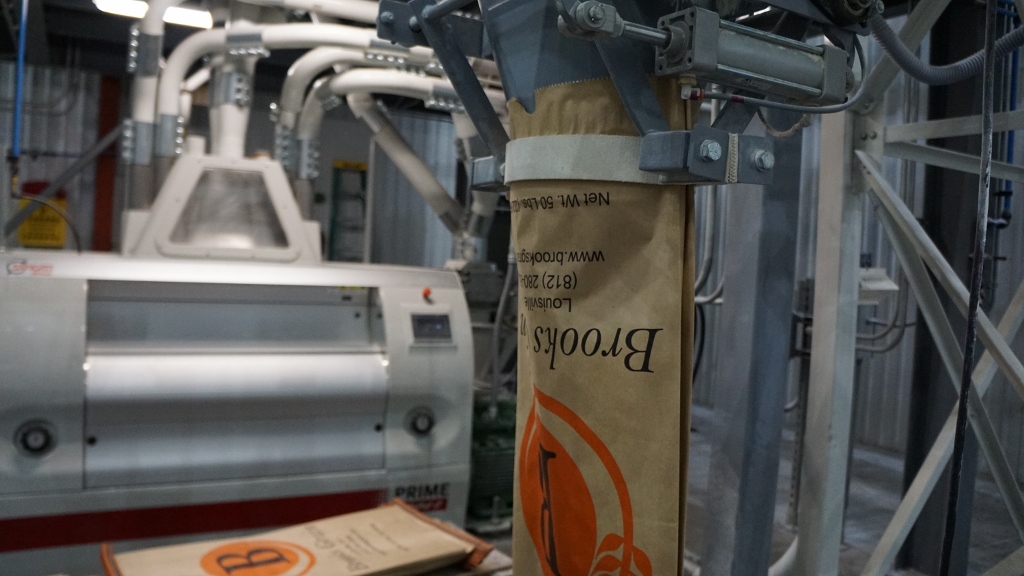

The new nearly 50′ tall milling operation is very flexible. Nathan Brunner, Facility Manager for Consolidated Grain and Barge Co. provided some insight into the mill and how things flow from the whole grains kept in the outdoor silos to the milling to the bagging and final stitching of the bags.

“This mill was designed and built to distribute into the distilling industry,” said Brunner. “It’s designed to be extremely flexible. We handle multiple commodities like rye, corn, malted barley and even specialty commodities like malted rye. Part of the mill system is pneumatic conveyance to help with clean out and handling multiple commodities. We have a destoner that allows us to clean the grain and it pulls out different FM (foreign matter) by weight using aspiration.”

“The mill is a Sangati Berga roller mill, it has a first break and a second break. That allows for good consistency in the product. To aid with that we have a sifter that distributes the grain by particle size. It allows us to make sure that everything that runs through the mill is consistent. Every customer is getting the same grains on a consistent basis.”

“One of the other key features of the mill is the flexibility to package in different sizes. A lot of what we do is 50lbs. bags but we also do 2,000lbs super sacks and 6.5 gallon/35lbs buckets. The whole process and operation is extremely flexible, it’s built to cater and support each individual customer in the craft spirits industry.”

The machinery can mill about seven tons of grain per hour. Interestingly they have to slow the mill down a bit when running rye. Nate said rye is a little bit tackier grain and it doesn’t flow through the pipes quite as well. I found this interesting because you hear similar things from distillers that when running a high rye mashbill they have to slow things down because the grain cooks and ferments very different from corn. This explains why rye whiskies or a high rye bourbon can often cost more than bourbons made with little to no rye grain.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

The entire operation is certified Kosher, organic and Kentucky proud. Their stock offerings include yellow corn, malted barley, wheat and rye. Specialty grains like flavored malts, white corn, blue corn, rye malt, oats and other grains are available by special request.

The milling operation actually started earlier this year and they have a growing list of craft distilling customers.

“Brooks Grain has been an integral component in our distilling process, the quality of milled grain is unsurpassed, their willingness to meet our needs is exceptional.”

Jodie Filiatreau, Artisanal Distiller Evan Williams Bourbon Experience – Louisville, Kentucky“Brooks Grain has proven to be a valuable partner to Swamp Fox Distilling Co. They are wonderful people to deal with and work very hard to insure that our grain arrives on time and is of the highest quality. I’ve even noticed a marked improvement in efficiency, yield and flavor since Brooks Grain became our supplier earlier this year.”

Britt Moon, Owner, Swamp Fox Distilling – Buena Vista, Georgia

Learn more about Brooks Grain.

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Twitter.