Templeton Rye has been bootlegging whiskey with their own recipe since the 1920s. According to family history, they were funneling whiskey to Chicago and the likes of Al Capone during Prohibition. For about seven decades, that family recipe wasn’t really used again until 2001 when the descendents Alphons Kerkhoff decided to restart the family business. It was around that time they found a partner to make whiskey with the family recipe and start Templeton Rye. In 2006 after aging for four years, the family was once again selling rye whiskey – only this time, it was legal.

Time to Build a Distillery

Templeton Rye Co-Founder Keith Kerkhoff at groundbreaking.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Fast forward 15 years and the family has decided to take the next big step and build their own distillery. Templeton Rye just raised a few highly polished shovels to celebrate the groundbreaking on their new 34,500 square foot distillery and an aging warehouse at its 20-acre facility in Templeton, Iowa.

“We’re moving full-steam ahead. Our company is laser-focused on bringing the history and spirit of the community of Templeton, Iowa, to life through Templeton Rye whiskey,” said Keith Kerkhoff, Templeton Rye co-founder whose grandfather was an area bootlegger. “We’re proud to share ‘The Good Stuff’ with whiskey lovers around the Hawkeye State and the country,” Kerkhoff concluded.

500,000 Proof Gallons Per Year

Distillation will feature a Forsyth still made in Scotland.

This evolution will continue to strengthen Templeton Rye’s Iowa heritage and celebrate the people and rich history of Templeton, Iowa. The new distillery will feature a Forsyth pot and column still that will have capacity to produce 500,000 proof gallons of rye whiskey annually. The new aging warehouse will be able to hold 40,000 oak whiskey barrels.

The project will increase the brand’s investment in its namesake town and keep with Templeton Rye’s long-standing tradition of giving back to the community. Over the years, the company has invested more than $1 million in the local economy and hosted more than 25,000 visitors at its current facility since opening to the public. Once completed, the new distillery is expected to add 30 new full-time jobs.

Templeton Rye’s Journey to Building a Distillery

Today’s Templeton Rye was introduced in 2006 using a recipe that best matched the recipe of Alphonse Kerkhoff, Keith Kerkhoff’s grandfather. Apparently, the family recipe had to be adjusted to meet today’s legal definition of a rye whiskey with a mashbill of at least 51% rye. Templeton’s current distillation takes place at MGP distillery in Lawrenceburg, IN with a mashbill made up of 95% rye grain. The distilled rye whiskey is brought to Templeton, Iowa, where it is combined with Templeton Rye’s proprietary formula and local purified water.

In October 2006, the first 68 barrels of Templeton Rye completed their four-year aging process, and became legally available on shelves in Iowa. The company expanded its plant from a small building, adding 11,000 square feet in 2007 for a more efficient production process. An automated bottling line went online in 2008, providing a quicker, more efficient method of bottling.

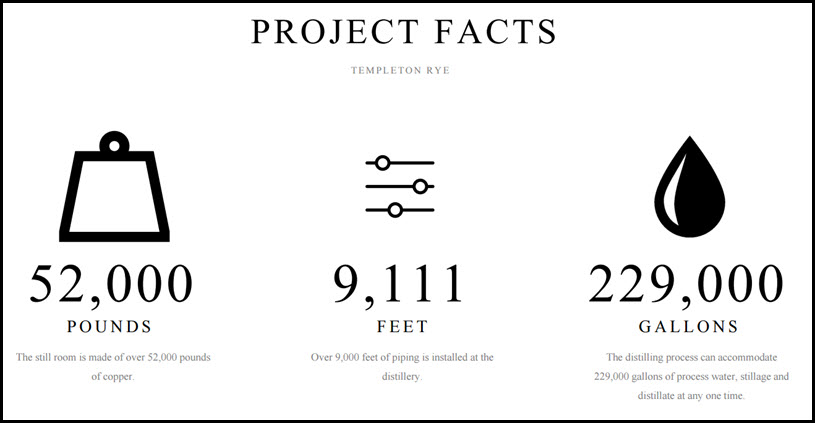

Over 52,000 lbs of Copper

ICC Turnkey says the still room will be constructed from 52,000 pounds of copper and over 9,000 feet of piping upon completion. The distilling process will be able to accommodate 229,000 gallons of process water, stillage and distillate at any one time within the process tanks.

The company expects the new Templeton Rye Distillery project to be completed in about 18 months.

Templeton Rye Distillery Renderings

Click on any image to enlarge.

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Twitter.

Related Links

Templeton Rye Distillery

View all Iowa Distilleries

Iowa Distillers Alliance

ICC Turnkey – Architects/Engineers