Patience, patience, patience. Just like a good bourbon takes time to mature, doubling bourbon production capacity takes time as well. Time and money, lots and lots of money.

Buffalo Trace Distillery located in Frankfort, Kentucky continues to make headway on their planned 10 year $1.2 billion bourbon expansion plans. The latest expansion news will bring a tear to the eye of Buffalo Trace fans. Among many other things the latest progress includes the doubling of distillation capacity.

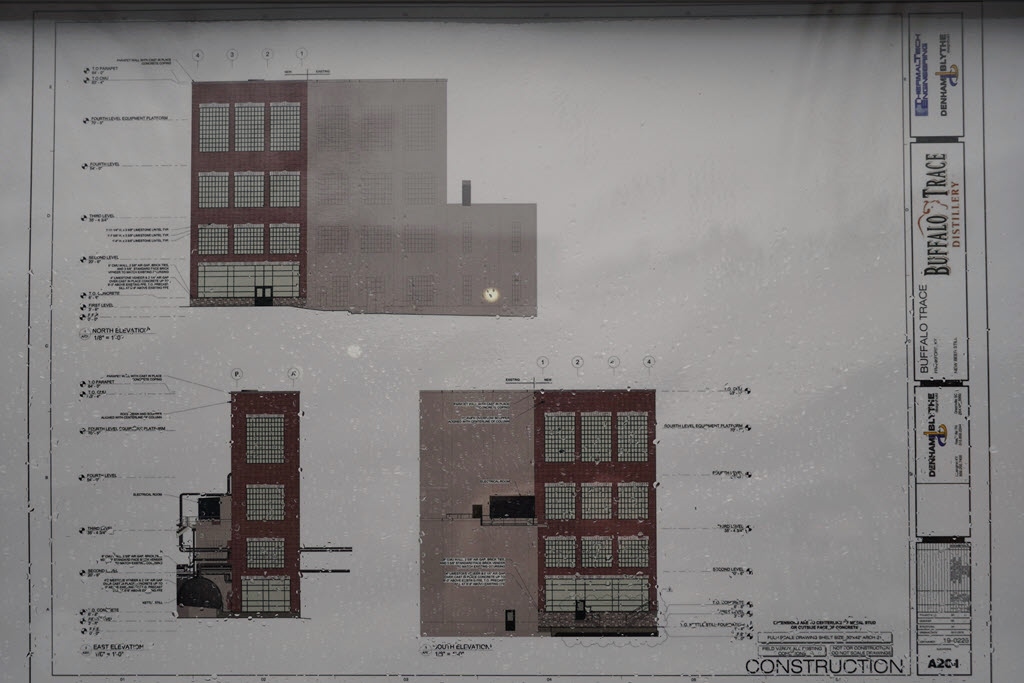

Recent expansion news has included new barrel warehouses, additional fermenters, expanding the dry house operation, expansion of the still house and the installation of a new Vendome Copper & Brass Works 40′ tall by 84″ copper column still.

“We’ve made great strides in our expansion so far, but we still have a long way to go in order to meet the needs of our fans,” said Master Distiller Harlen Wheatley. “We continue to take all the proper steps to ensure every barrel is of the highest quality as we increase supply.”

Watch the video below to see the new column aerial lifted into the new still house.

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

New Buffalo Trace Still Will Double Bourbon Production

The second still required the building of a new still house right next to the existing 1930’s still house. The newly installed column and high and low wine condensers will allow having the capacity of 60,000 gallons allowing them to double bourbon whiskey production.

Eight additional fermenters were added and went online in January 2021, joining the four new fermenters added in December of 2019 and bringing Buffalo Trace’s total fermenter count to 24. The new fermenters are 93,000 gallons each, slightly larger than the twelve older fermenters Buffalo Trace still uses, which have been in place since 1933.

“The bourbon category continues to grow at a rapid rate, and while we have been increasing production across our portfolio for the last several years, we are still catching up to consumer demand,” said Sara Saunders, vice president of marketing, Buffalo Trace Distillery.

“While we are producing and shipping a record amount of product, we understand the frustration from fans that our brands aren’t easy to find or readily available. We take pride in the quality of our product above all else, and we believe that there is no substitute for aging. Unfortunately, this lengthens the lead time of getting product into consumers’ hands.”

What Happens with All that Stillage (Spent Grains)?

For every gallon of bourbon produced, approximately 10 gallons of stillage remains and it all has to go somewhere.

One of the more interesting construction projects started in the past year involves repurposing the oldest aging barrel warehouse on property, Warehouse B, to a new dry house. Warehouse B was built in 1884 but has sat empty for two decades after it was determined that it was not ideal for aging the quality whiskey Buffalo Trace requires with today’s rigorous standards. An all-brick warehouse, its location at the back of the distillery near the cookers and fermenters made it an ideal location for drying spent mash to sell to farmers for livestock feed and it allows the distillery to repurpose the building while maintaining its historic integrity. Buffalo Trace’s existing dry house will continue to operate once the new dry house is complete, but the additional dry house is necessary for the increased production. The distillery’s dry house operations ensure that none of the distillery’s byproduct goes to waste.

A new cooling system is also underway, which includes mash coolers, chillers and cooling towers, all necessary to cool the mash down after cooking so it can be transferred to fermenters as needed.

Distilling Requires Lots of H2O – Water in / Bourbon Out

Distilling operations require lots of water. The water is required not just for making bourbon but for continuously cleaning the machinery that makes it all possible.

The distillery has broken ground on a $40.0 million wastewater treatment facility, allowing it to be self-sufficient in its treatment of wastewater. Comprised of a moving bed biofilm reactor, the new treatment facility will allow wastewater to be treated efficiently and maintain water quality standards. Wastewater will be treated and disinfected clean enough to release into the Penitentiary Branch, which leads to the Kentucky River —ensuring both remain high-quality waters.

58,800 Barrels Rickhouses Continue to Go Up to Store Maturing Bourbon

New barrel aging warehouses HH, II, and JJ have also been added in the past year and LL and MM are under construction now. Warehouses KK and NN are in the planning stages. Since most of Buffalo Trace’s bourbons age eight to 10 years, more warehouses continue to be built as production increases. A total of 10 new barrel warehouses have been built to date since 2017, each holding 58,800 barrels and costing about $7 million each to build and another $21 million each to fill with barrels.

The progress made over the past year joins previous expansion items as part of Buffalo Trace’s $1.2 billion investment, such as four new 22-foot tall cookers, four new fermenters, a 110,000 square foot bottling hall, and an expanded Visitor Center which triples the size of the former retail, tasting and event space.

Upcoming infrastructure projects for this 246-year-old Distillery in the near future include a new mill house, which will be located close to the original location of the hammer mill from 80 years ago. The mill house will increase the grain grinding capacity to match new distillation capacity by replacing the current hammer mills. Corn, wheat, rye and barley are trucked into Buffalo Trace from various non-GMO farmers in the region, but then must be ground on site before the grains can be used to make bourbon.

More barrel aging warehouses are also planned for the future, as well as another craft bottling hall which will allow Buffalo Trace to produce more single barrel and small batch bourbons.

Bourbon Fans Continue to Flock to Buffalo Trace Distillery

Buffalo Trace resumed tours over a year ago after a brief shut down due to COVID-19 and visitation has rapidly picked up pace, while maintaining safety protocols. Since re-opening last July, Buffalo Trace has seen more than 235,000 visitors, despite some capacity restrictions still in place. If you are considering visiting the distillery go online and book well ahead of time (think weeks not days here), Buffalo Trace free tours fill up quickly.

When Will Expanded Distillation Production Start?

The Summer of 2022

And in regard to that giant column still. It’s expected to begin distilling sometime in summer of 2022. Add to that four plus years of aging for bourbon and it will still be a while before Buffalo Trace catches up with demand. Patience, patience, patience. Cheers!

Learn more about Buffalo Trace Distillery.

View all Kentucky Distilleries.

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Instagram and Twitter.