The still is the heart and soul of your distillery. Your still will determine the type of spirits you can make and the volume of spirits you can produce on a daily, weekly and annual basis. And as the importance of distillery tourism continues to grow the design of your still helps to tell a story that will educate and entertain your fans in a way that will have them sharing your story with all their friends and family. Choosing the right type of still and the right size still is just the beginning of your distillery journey.

How to Choose the Right Still for Your Distillery

Batch Pot Still vs. Continuous Column Still

The checklist you are about to read will help to prepare you for your first conversation with your still builder and will set you on a path that will help you produce spirits today and well into the future.

Choosing the right still is no easy task. Choosing the wrong still can be very expensive. Choosing between a pot still or a column still is just the beginning. When referring to these two systems its best to think about them with their full names so instead of pot still vs. column still you’re really choosing between Batch Pot Still system vs. a Continuous Column Still system.

DistilleryTrail met with fourth generation still builder Rob Sherman of Vendome Copper & Brass Works to step through the process of how to choose the right still for your distillery. Vendome and the Sherman family have been building stills at the same location for more than a century and is now one of the premiere builders of distillation equipment in the world. You’ll find their stills, fermentation tanks, mash tuns, beer wells, spirit safes and more in startup craft spirits distilleries to large heritage distilleries like Jim Beam, Jack Daniel’s, Four Roses, Old Forester, Michter’s and many, many more. The look and feel of their equipment runs from utilitarian to the intricate 420 piece Walker Woodfill spirit safe at Wilderness Trail Distillery. Not only do they build and install all their systems but they’ve been servicing them for just as many years. And for craft spirits makers that are more of a do-it-yourselfer they’ll drop your new still off and you can install it yourself.

Questions to Answer When Deciding on

What Still to Order for Your Distillery

Everyone’s starting point is different. Some people are expanding from brewing to distilling and will have a good base line. Some will have worked in another distillery and are ready to take the plunge to start their own distillery. While others are just getting started on their distillery journey and will need help with every step along the way. This is a general order but all the topics are critical to the decision making process. Let’s get started.

- What distilled spirit(s) do you want to make? Whiskey, moonshine, bourbon, gin, vodka, brandy, absinthe, etc.

- How much of each spirit do you want to make? Proof gallons or barrels per day, week, month or year.

- Are you distilling or brewing now?

- Is this your first distillery?

- How much do you want to work? Think about operations and production. The answer to this question is not as simple as you might think. Here are a few things to consider.

- How many days per week will you be distilling?

- How many shifts – one, two or three?

- How long is each shift

- 100,000 proof gallons a year with one shift?

- 100,000 proof gallons a year over four different products.

- Will you be making bourbon or whiskey?

- How many barrels per day?

- A 1,000 Gallon pot still can make about 2 barrels per day, where a continuous still running 1,000 gallons of beer will produce 2.3 barrels per day. Depending on ABV of beer.

- If making more than 2 barrels per day consider a continuous column still vs. batch pot still

- If making 1 to 2 barrels per day then stick with a batch pot still

- If making more than 2 barrels per day consider moving to a continuous column still

- Will you be running a Sweet Mash or Sour Mash process?

Where will you store your filled barrels? Whether you call it a barrel warehouse, rickhouse or rackhouse you may be surprised how quickly they can fill up. How many months will it take before you fill up that barrel storage space? And if you are on the second floor don’t forget how heavy barrels can get. A 53 gallon barrel will weigh more than 500 lbs. each.

Are you running a show for tourists?

Honey House Distillery.

Creating an experience for tourists may not have mattered 100 year ago (except for Colonel E.H. Taylor Jr.) but in today’s distillery tourism environment the look of your equipment is very important. Customers expect to see fermentation tanks with bubbling mash and a beautiful steaming still.

Copper or stainless steel? Do you prefer a copper still naturally patinad from years of usage or a finish that is polished to a mirror like finish? Are you in a historic building or district and want to stay true to the fabric of the neighborhood or are you in an urban environment and looking to draw a crowd that will post, share, rate and review your distillery like crazy on social media.

“If you are not running a show for tourists every day you can run a 12″ column still one day per week instead of a pot still five days per week. You will make better more consistent product and you can fill all your barrels on one or two days per week,” said Sherman.

- Do you already have a site selected?

- Do you own the property and building or are you leasing?

- Set up costs can be considerable if you are thinking you may move soon

- Is this a long term or short term location?

- Will you pick up production and move to another location?

- Ready to move skid system? Consider a portable system built on a skid where the main components can be picked up and moved on a flatbed truck.

- The Building – What kind of building will be home to your distillery operation?

- Existing Structure

- First floor, second floor, etc?

- Can it handle the weight of the equipment when fully loaded? A fully loaded 10,000 gallons mash tun filled with steaming mash can weigh well over 40 tons.

- Ceiling height restrictions? Max height of equipment?

- Can you raise the roof to accommodate a continuous column still?

- Access points – Drop still in through roof? Drive in via a fork lift?

- Neighbors – Will delivery trucks have direct access to your distillery during construction and afterward for daily operations?

- Historic – Are you considered a National Historic Site? That’s great but it often changes the rules of what you can and cannot do to modify an existing structure.

- What state are you in? Local, city and state regulations vary widely by location.

- Is it a standalone building or a location with other retail outlets like a restaurant or apartments? Fire detection and suppression must be considered under various scenarios.

- Point of entry for dry good coming in and dry goods going out

- New Construction

- Height

- How many square feet inside the building

- Room for expansion?

- Is it already designed or can you make changes based on the distillation equipment recommendation?

- Existing Structure

Dry Counties in the United States

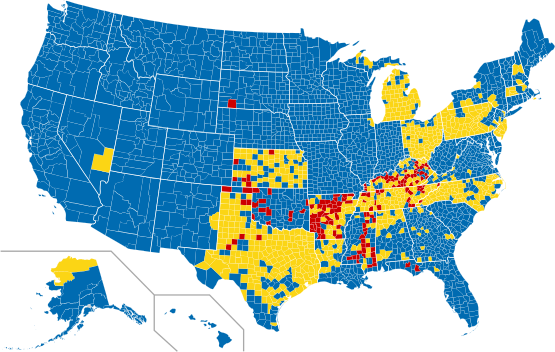

Are you in a wet, dry or moist county? It’s hard to believe but even in Kentucky, the home to 95% of the world’s bourbon 38 out of the 120 counties are still considered dry. To be clear, some are totally dry, some are wet and some are mixed and often referred to as moist. In a moist county there may be areas within the city limits that allow the sales and serving of alcohol while the rest of the county is dry as a bone.

Dry Counties in the United States – As of May 2019, Red is Dry, Blue is Wet, Yellow is Mixed (Moist.)

- What utilities do you have available?

- Water

- City, river, creek, well, geothermal

- What’s the flow rate? At least 6 gallons/minute.

- What’s the average temperature? Heating and cooling of and with water is a huge part of the distillation process.

- Water

-

- Energy

- Natural Gas or Propane

- Electric – Single, 3 Phase, 230 V, 460 V

- And don’t laugh – Wood fired or coal fired?

- Energy

- Will you be milling grains or purchasing pre-milled grains?

- What will you do with all those spent grains and used water?

- Can you discharge slop directly into the city sewage system?

- Will they charge you for waste discharge

- Will you give spent grain away to local farmers? How much slop will you need to hold before you have to stop production? What if the farmer doesn’t show up?

- Will you dry spent grains partially before distribution

- What distilleries have you toured? Anything stand out that you would like to replicate or avoid?

- Special features – copper, stainless steel, glass, spirit safe, etc.

The Spaghetti Sauce Example

Batch Pot Still vs. Continuous Column Still“Spaghetti sauce has garlic and peppers and all these other ingredients, your tomato sauce and all that. When you put that in a batch still the first thing you are going to get is all the garlic off, it’s the low boiler, it comes off first, it tastes terrible you throw that away (the heads)”, said Sherman. “Then you get your middle part that might have a little bit of garlic left, a little bit of everything and it tastes good (the hearts.) And the tails would be whatever else is left but it’s concentrated on the end. So a batch still concentrates those different alcohols.”

“A continuous still you are pulling a cut right out of the center. Which will have a lot of garlic in it and a lot of your heads, a lot of your tails that will turn into desirable notes in the barrel. But you are getting less heads and tails on continuous than a batch. Because a batch is actually producing more and condensing more, concentrating more. If you ran the exact same mash bill on a pot and a continuous next to each other and they come off at the same proof, they’ll taste totally different as a raw (white dog) spirit. Think about it like cooking a soup. A soup that’s been in a pot for two or three minutes doesn’t taste anything like a soup that’s been in there for six or eight hours simmering even though it’s the same ingredients. In simple terms, that’s the philosophy.”

“The people that use a continuous still and are familiar with them and use them can control them. You have a pretty good range, you can control bottoms loss, venting heads, you can change flavor profiles pretty easy by different reflux points so they are pretty controllable.”

The Ultimate Distillation System for Your Distillery

“Some people buy a continuous column still with a doubler for barreled products. And then some people replace their doubler with a spirits still, so they can use the continuous still, the spirits still as a doubler, fill barrels, then if they want to make gins, rums, vodkas, they can go to the spirits still and run a batch off the same system. Then some people buy the continuous still for the barreled products and then buy a separate spirits system and a vodka column to do everything else, gins, vodka and maybe different kinds of ryes. That’s probably the ultimate system, if you buy a continuous column with a doubler and then buy a spirit still with a vodka column you can pretty much do anything you want. Make every product there is.”

“The two things that determine to me whether they want continuous or batch is the size of the system and how much product they are going to put into the barrel. You can make really good bourbons and whiskeys on a pot still it’s just harder to do over and over consistently. If you are going to fill barrels every day, making the same product or varying between bourbon, ryes or single malts the continuous still can do it consistently every day, day in and day out. With a pot still you are depending on every variable staying the same every time you run it. It has to run the exact same amount of time, with the exact same mashbill, exact same fermentation, exact same cuts, exact same temperatures on your water, exact same temperature on your heat up and cool downs. If any of that changes then you get a little bit different product. That’s why you have to blend.”

- Are you going to be a production facility or a tourist destination?

- What look are you going for?

- Patina

- Highly polished

- Special features

- What’s the look in the day? What’s the look at night?

- Expansion plans – Can this equipment help you to expand?

- Do you have the floor space?

- More equipment or more hours?

- Hours worked – 1 shift at approximately six hours per day. Add a 2nd and/or 3rd shift?

- How many days per week? 24/7?

- Add a stripping still on the front end

- Add a drop tank for cooling mash prior to fermentation

- Increase size of a fermentation tank or add additional fermentation tanks

- Can the existing batch pot still or continuous column still handle more volume

- Mashing the grains

- Cooking

- Fermentation

- Distillation

- Are you working with a distillery consultant, architect or engineering firm? We know several.

When Do You Start Talking to Your Still Builder? The Sooner the Better!

“A lot of times I’m the first guy they talk to,” said Sherman. “They are really just trying to figure out where to go and how to get going. I’ll send them to consultants that will help to walk them through everything. Recommend architects, engineering companies, fire marshal consultants, TTB consultants, pretty much everything they need to get going. A lot of times I’ll tell them to take the Moonshine University course depending on what state they are in. You’ll leave there with a binder that has everything you need there and it will save you 10x what you spent there.”

“If they can’t decide on a continuous or a batch and need help on sizes nailed down I’ll give them a list of distilleries they can go visit. I’ll try to find something close to them. I’ll tell them to visit the distillery, talk to the owners. When they come back after that they know what they want. They can see it running, talk to the owner and they’ll tell I wish I went bigger, I wish I hadn’t bought this, I wish I went this way, that’s the best advice for them. A lot of the continuous stills we sell the people are dead set on pot stills when they walk in the door. Go talk to these people, take some tours and decide what you need. Touring other distilleries is huge on helping them to decide what they want.”

Economies of Scale – There is a fine balance between building what you need and planning for expansion. As with most production facilities, people are often the most expensive part of the production cost.

“The cooker is the work horse of the whole distillation process. It does the most work and takes the most abuse. We try to size our cookers so we turn a cooker every four hours. So you literally could get five to six cooks per day out of one cooker in 24 hours. As you are sizing up from one shift to two or three shifts that cooker can handle it. It can take enough cooling water, it’s got enough square footage and enough steam that it can handle it.”

What’s the First Step?

Get on the Production Calendar, Order the Equipment,

Figure Out the Look Later

“How ornate do you want your system to be? Deliveries can run eight to 12 months and our copper order has to be placed well in advance of that. The main body of the equipment can be on order and then the fancy stuff can be discussed in the interim – glass features, logo plates, kinetic spirit safe, etc.”

Ready to Get Your Distillery Started?

Talk to Vendome Copper & Brass Works.

Call Us Now at 502-587-1930

We’ll Help to Craft Your Dream!

Email: Office@VendomeCopper.com

Click Here to Download Vendome Copper & Brass Works

Distillation System Brochures

What is BrandScape? BrandScape is a way for product and service suppliers to talk directly to our audience. If you would like to learn more about BrandScape, please email Info@DistilleryTrail.com.